filmov

tv

Climbing Sling Myths

Показать описание

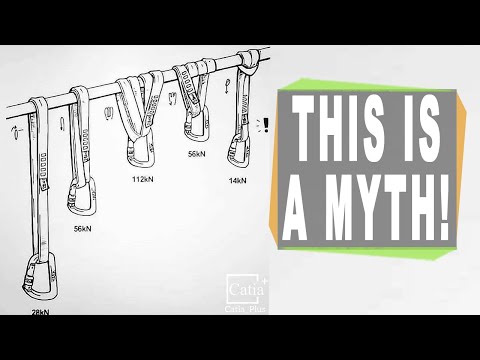

The image of a sling straight vs doubled vs girth hitched and it's relative strengths float around and is taken as doctrine. So we tested it.

Straight (broke 30%+ above MBS or the same as the chart)

Test 1: 29.02kn

Test 2: 27.62kn

Doubled (should get around 56kn)

Test 3: 53.58kn

Test 4:52.26kn

Wrapped 3x (should get around 56kn)

Test 5: 43.90kn

Test 6: 47.76kn

Doubled Twice (should get around 112kn)

Test 7: 78.72kn

Test 8: 82.82kn

Girth Hitch (should get 50% or 14kn)

Test 9: 25.22kn

Test 10: 23.48kn

Girth hitch with a 22kn MBS dyneema sling 15.48kn

Girth hitch nylon sling directly on hanger 9.50kn

Intro

00:41 The Test

03:41 Reddit

07:29 Straight

08:02 Doubled

09:04 Wrapped

10:26 Doubled Twice

13:11 Girthed

15:02 Conclusion

17:05 Extra Test

18:48 Ending

Straight (broke 30%+ above MBS or the same as the chart)

Test 1: 29.02kn

Test 2: 27.62kn

Doubled (should get around 56kn)

Test 3: 53.58kn

Test 4:52.26kn

Wrapped 3x (should get around 56kn)

Test 5: 43.90kn

Test 6: 47.76kn

Doubled Twice (should get around 112kn)

Test 7: 78.72kn

Test 8: 82.82kn

Girth Hitch (should get 50% or 14kn)

Test 9: 25.22kn

Test 10: 23.48kn

Girth hitch with a 22kn MBS dyneema sling 15.48kn

Girth hitch nylon sling directly on hanger 9.50kn

Intro

00:41 The Test

03:41 Reddit

07:29 Straight

08:02 Doubled

09:04 Wrapped

10:26 Doubled Twice

13:11 Girthed

15:02 Conclusion

17:05 Extra Test

18:48 Ending

Climbing Sling Myths

THAT DMM climbing video: the myths and misinterpretation, many years on! Knots in Dyneema slings.

Shockloading Highlines is a Myth - more human testing

Not all climbing anchors are bomber

Carabiners and Slings on Harness

Slings vs Lanyards vs Personal Anchors - Differences, Usages & Safety Musts | Ep.3

If you do this, DON'T do it wrong!

It's NOT what you think

American Death Triangle is a Myth

“Worlds MOST DANGEROUS knot”… or Most Useful!?

Climbing Quad Anchor break test with 240cm Black diamond dyneema sling

Climbing Slings, Climbing Knots, and Climbing Anchors: Are Knots in Slings a Good Practice?

You aren't supposed to tie a knot in this

Gripped Climbing Magazine exposed some Newbs

290lb (131kg) climber! Guess the forces.

Is Equalization a Myth on Highline Anchors??? 2 guys + 5 dynomometers + 13 anchors!!!

This trick changes everything

Mechanical Advantage is a Myth

Sketchy carabiners from Amazon, AliExpress, Ebay and Walmart tested!

20 Pro Tips EVERY Climber should know

Does climbing gear pulling out soften the blow on the next piece?

'It won't hurt you,' they say

MBS (Minimum Breaking Strength) on Climbing Gear is a Myth

Prusik, Auto Blocks, and Klemheist Break Tests

Комментарии

0:17:06

0:17:06

0:16:21

0:16:21

0:11:32

0:11:32

0:11:56

0:11:56

0:00:48

0:00:48

0:26:56

0:26:56

0:09:15

0:09:15

0:10:13

0:10:13

0:24:56

0:24:56

0:00:42

0:00:42

0:16:39

0:16:39

0:08:47

0:08:47

0:20:07

0:20:07

0:05:05

0:05:05

0:00:26

0:00:26

0:24:36

0:24:36

0:08:58

0:08:58

0:12:44

0:12:44

0:10:48

0:10:48

0:16:41

0:16:41

0:07:25

0:07:25

0:18:43

0:18:43

0:24:49

0:24:49

0:13:44

0:13:44