filmov

tv

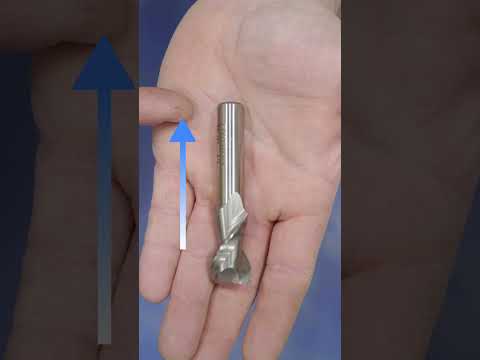

The Router Bits - Better Router Raising

Показать описание

Triton Router

Router Lifts

Round Body Motor System

In this episode of The Router Bits, Patrick discusses different ways your router can be raised and lowered in your router table. He begins with the Triton system, moves on to dedicated router lifts and then finally discusses his preference - the round body motor.

Take The Guesswork out of Height Adjustment

Routing can bring high-level machining accuracy to any woodworking project. Even the slightest unsightly gap can create a lot more hard work fixing the problem, or end up wasting valuable material. The Sherwood Router Lift fixes one axis of adjustment by bringing perfect accuracy to bit height adjustment.

The 298 x 235mm top mounting plate is identical to the standard aluminium router mounting plates- milled and CNC-machined from 6mm-thick aluminium plate. Over and above the standard mounting plate, a few extra holes are machined to mount the lift assembly underneath. The aluminium is anodized and then checked for flatness after this important step. Where necessary, each plate is checked and adjusted for flatness for a perfect smooth surface closest to the bit - where it matters most.

Supercharge Your Lift.

Now available is the Sherwood Round Body Router Motor - the perfect companion for your router table when paired with this lift.

With 2400W (3 1/4HP) input and 1800W (almost 2 1/2HP) output, this router motor is perfect in virtually every way for router table applications. It is the standard 106.7mm (4.2in) diameter - the exact same diameter required for the Sherwood Router Lift.

It runs on standard 240V with a 10-amp ANZ plug and can be mounted perfectly in the lift in a matter of a few minutes and gives you everything you need in a table motor without forcing you to pay for extras that you will never use (like the plunge bases integral to most Australian-sold routers)!

Make no mistake about it, this is an industrial grade motor that gives you a continuously adjustable variable speed that allows you to reach 10,000-22,000 RPM and everywhere in between. You have a dial that is a marked improvement from the preset positions found on the typical 5 speed switch from the Porter Cable motor.

The ability to maintain speed under constant load speaks volumes to how well this motor is engineered. Not to mention that we went the extra mile to seal out dust from this variable speed dial.

It comes standard with a dedicated 1/2in and 1/4in chuck plus the two spanners that enable above-table bit changes with ease.

Industrial Power.

Fixed base router motors are not commonly available in Australia with 240V power, however Sherwood have delivered a water-cooled CNC spindle with an adapter to mount in this lift - an Australian first.

The CNC spindle body is 80mm and doesn't have any mounting grooves for the base like the routers in North America. For extra safety, a groove is machined into the spindle body and a spring washer is installed. A matching groove is machined into the adapter so that when combined with the spring washer on the spindle, it locks the spindle in place inside the adapter. This extra safety step means that no matter what vertical pressure is placed on the spindle - it is held captive in the adapter.

Router Lifts

Round Body Motor System

In this episode of The Router Bits, Patrick discusses different ways your router can be raised and lowered in your router table. He begins with the Triton system, moves on to dedicated router lifts and then finally discusses his preference - the round body motor.

Take The Guesswork out of Height Adjustment

Routing can bring high-level machining accuracy to any woodworking project. Even the slightest unsightly gap can create a lot more hard work fixing the problem, or end up wasting valuable material. The Sherwood Router Lift fixes one axis of adjustment by bringing perfect accuracy to bit height adjustment.

The 298 x 235mm top mounting plate is identical to the standard aluminium router mounting plates- milled and CNC-machined from 6mm-thick aluminium plate. Over and above the standard mounting plate, a few extra holes are machined to mount the lift assembly underneath. The aluminium is anodized and then checked for flatness after this important step. Where necessary, each plate is checked and adjusted for flatness for a perfect smooth surface closest to the bit - where it matters most.

Supercharge Your Lift.

Now available is the Sherwood Round Body Router Motor - the perfect companion for your router table when paired with this lift.

With 2400W (3 1/4HP) input and 1800W (almost 2 1/2HP) output, this router motor is perfect in virtually every way for router table applications. It is the standard 106.7mm (4.2in) diameter - the exact same diameter required for the Sherwood Router Lift.

It runs on standard 240V with a 10-amp ANZ plug and can be mounted perfectly in the lift in a matter of a few minutes and gives you everything you need in a table motor without forcing you to pay for extras that you will never use (like the plunge bases integral to most Australian-sold routers)!

Make no mistake about it, this is an industrial grade motor that gives you a continuously adjustable variable speed that allows you to reach 10,000-22,000 RPM and everywhere in between. You have a dial that is a marked improvement from the preset positions found on the typical 5 speed switch from the Porter Cable motor.

The ability to maintain speed under constant load speaks volumes to how well this motor is engineered. Not to mention that we went the extra mile to seal out dust from this variable speed dial.

It comes standard with a dedicated 1/2in and 1/4in chuck plus the two spanners that enable above-table bit changes with ease.

Industrial Power.

Fixed base router motors are not commonly available in Australia with 240V power, however Sherwood have delivered a water-cooled CNC spindle with an adapter to mount in this lift - an Australian first.

The CNC spindle body is 80mm and doesn't have any mounting grooves for the base like the routers in North America. For extra safety, a groove is machined into the spindle body and a spring washer is installed. A matching groove is machined into the adapter so that when combined with the spring washer on the spindle, it locks the spindle in place inside the adapter. This extra safety step means that no matter what vertical pressure is placed on the spindle - it is held captive in the adapter.

Комментарии

0:22:13

0:22:13

0:08:26

0:08:26

0:13:47

0:13:47

0:00:24

0:00:24

0:09:57

0:09:57

0:12:26

0:12:26

0:00:39

0:00:39

0:00:30

0:00:30

0:08:02

0:08:02

0:08:02

0:08:02

0:01:42

0:01:42

0:06:19

0:06:19

0:05:50

0:05:50

0:00:46

0:00:46

0:06:33

0:06:33

0:04:21

0:04:21

0:04:00

0:04:00

0:05:36

0:05:36

0:07:37

0:07:37

0:08:27

0:08:27

0:06:57

0:06:57

0:12:15

0:12:15

0:09:55

0:09:55

0:15:15

0:15:15