filmov

tv

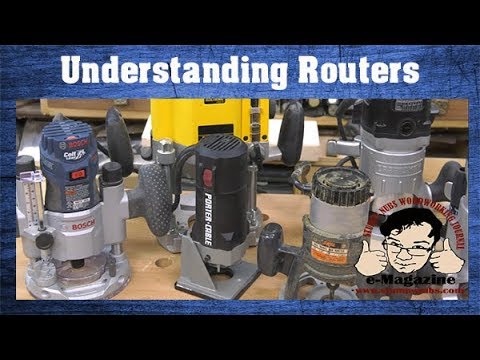

Don't Buy a WOODWORKING Router or Bit Before Watching This | Beginners Guide

Показать описание

Beginners guide to woodworking with Routers, Router Bits, and Templates. This video will help you decide what router setup is best for your woodworking goals and budget.

Favorite Bit Links -

Favorite Routers affiliate links -

Vacuum affiliate links -

More router Info Videos

My Links -

Favorite Bit Links -

Favorite Routers affiliate links -

Vacuum affiliate links -

More router Info Videos

My Links -

Don't Buy the Wrong Router #woodworking

Don't Buy a WOODWORKING Router or Bit Before Watching This | Beginners Guide

You Don't Need a Full-Sized Router! (Try This Instead...)

Don't buy this finger joint router bit

DON'T buy a router table - DO this instead!

WATCH THIS before you buy a router! (A lot of stuff you may not know!)

99% of Beginners Don't Know the Basics of Router Bits

DeWALT Just Changed Woodworking FOREVER (genius new router)

Romany caravan dolls house pt 6 #palletwood #scrapwood #woodendollshouse

Don't Pick The Wrong Router for #woodworking

This Is Why You Should Never Buy Cheap Router Bits On Amazon! DON'T BUY CHEAP TOOLS!

DON’T Buy a Router Table!!! Build THIS ONE Instead

Don't buy a router plane! Build one instead.

Which Compact Router Should You Buy? - Toolsday Woodworking Tool Reviews

Watch This Before Buying Spiral Router Bits

What Size Router Should you Buy First?

Why you DON'T do this on Router Tables

Don't Buy A Small CNC Router!

every woodworker needs these router bits

The Best Woodworking Router for Beginners!

Essential Router Skills - Tips, Tricks and Buying Advice

DON'T make these Router Sled Mistakes! | Evening Woodworker

Must-Have Router Bits for Beginners

Testing the CHEAPEST Woodworking Router on Amazon

Комментарии

0:00:38

0:00:38

0:15:15

0:15:15

0:09:11

0:09:11

0:06:09

0:06:09

0:17:34

0:17:34

0:08:16

0:08:16

0:22:13

0:22:13

0:15:57

0:15:57

0:00:57

0:00:57

0:00:51

0:00:51

0:04:29

0:04:29

0:28:15

0:28:15

0:08:47

0:08:47

0:17:08

0:17:08

0:10:02

0:10:02

0:10:33

0:10:33

0:14:09

0:14:09

0:00:43

0:00:43

0:10:24

0:10:24

0:09:55

0:09:55

0:13:09

0:13:09

0:08:32

0:08:32

0:00:53

0:00:53

0:15:13

0:15:13