filmov

tv

Drill big holes in 1' thick steel - Fastest way? - Iron - Metal - Aluminum - Large Drill Press

Показать описание

Just a quick video showing multiple ways to drill big holes in thick steel. We were using 1" thick steel flat bar. Showing how use different types of drill bits to put large holes in big pieces of metal. We timed each process to detremine which way is faster?

First we used an annual cutter, next up 3 different size twist drills, and lastly a regular hole saw. You might be surprised with the results.

You could easily use this same fast process to drill big holes in aluminum, iron, arn, and metal.

These are basic processes and skills

Follow me on Social Media:

Patreon:

First we used an annual cutter, next up 3 different size twist drills, and lastly a regular hole saw. You might be surprised with the results.

You could easily use this same fast process to drill big holes in aluminum, iron, arn, and metal.

These are basic processes and skills

Follow me on Social Media:

Patreon:

how to drill a hole in stainless steel for steel drill bits for metal 2022#

Drill big holes in 1' thick steel - Fastest way? - Iron - Metal - Aluminum - Large Drill Press

The Work Around: How to Drill Big Holes Into Wood | HGTV

FASTEST DRILL BIT For Drilling Large Holes?! (Speedbors Explained--How To Bore Large Holes Quickly!)

How to Drill Holes in Metal: Master the Drill Press

#1 Easiest Trick to DRILL STRAIGHT! (Drill at Perfect 90 Degrees...Fastest Method!)

How to Use a Diamond Core Drill - The Secret To Making Big Holes

5 Drill Bits You Need and 1 That's a Waste of Money

The easiest way to drill large holes in thick metal | Impacta step cutter

How To Drill Holes In Steel - The Ultimate Guide!

wall hole saw high performance utility tool drilling drill bit

💡 Simple trick: drill aligned holes through the middle of a pipe

CRAZY Drill Bit for big holes in Thick Metal + This Old Tony Tribute!

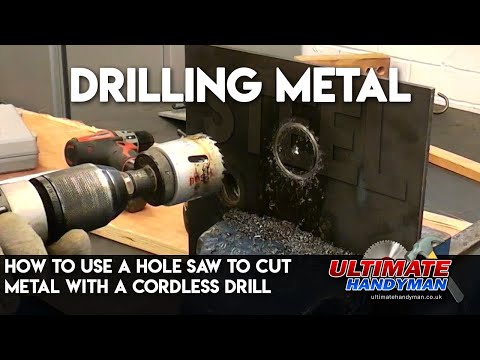

How to use a hole saw to cut metal with a cordless drill

10 Amazing and Useful Drill Bits !!

How to Properly Drill a Hole in Metal

Drill Bits #shorts

How to Drill Through Steel Beams with a Cordless Drill

How to Drill a Hole in Metal (1/4' Steel)

How to Drill a Large Hole in a Brick Wall - Diamond Coated Hole Saw

Drill deep hole in end-grain

Re-drill Holes in Metal and I-beams

How to enlarge a hole saw or core drill hole

Best wood drill bit for FAST clean deep holes

Комментарии

0:00:13

0:00:13

0:11:35

0:11:35

0:01:47

0:01:47

0:05:13

0:05:13

0:13:59

0:13:59

0:03:10

0:03:10

0:08:23

0:08:23

0:11:05

0:11:05

0:08:04

0:08:04

0:38:44

0:38:44

0:00:14

0:00:14

0:02:20

0:02:20

0:13:41

0:13:41

0:05:41

0:05:41

0:06:18

0:06:18

0:17:05

0:17:05

0:00:31

0:00:31

0:11:11

0:11:11

0:08:49

0:08:49

0:01:06

0:01:06

0:04:09

0:04:09

0:02:39

0:02:39

0:02:30

0:02:30

0:03:17

0:03:17