filmov

tv

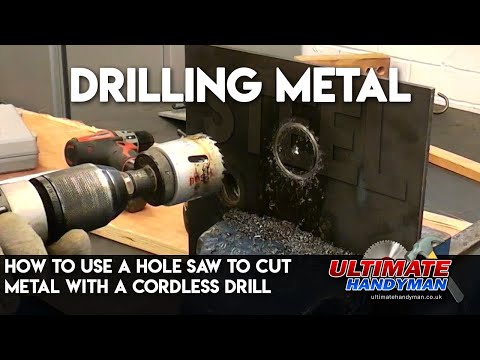

How to use a hole saw to cut metal with a cordless drill

Показать описание

How to Use a Hole Saw | Ask This Old House

How to drill and tap a hole (In 3 mins)

How to Enlarge a Hole With a Hole Saw

How To Use a Pocket Hole Jig

Beginner's guide to pocket hole joinery | WOODWORKING BASICS

Pocket Hole Perfection! 7 Expert Tips for Beginner Woodworkers!

How to use a hole saw

Top 13 Pocket Hole Tips and Tricks | ULTIMATE Guide To Become a Pro

The planets||sun||star||black hole||univers|| #space ||🌌 please use head phone or air pods ||

How To Use A Pocket Hole Jig

How to use a hole saw to cut metal with a cordless drill

Hole Saw Tip #diy #woodworking #youtubeshorts #carpenter

How to use a Kreg Pocket Hole Jig, one of the best tools for DIY

10 Pocket Hole Tips And Tricks

Drilling Holes In Wood - Hole Saws, Spade, Augers, Self-Feed & Forstner Bits

How to Use a Kreg Pocket Hole Jig 320

How To Use The Extra Shoelace Hole On Sneakers

How To Assemble & Use Quick-Hitch Arbor To Hole Saw

10 Helpful Pocket Hole Joinery FAQs For Beginners

How to Drill Hole in Walls for Mounting?

How to use a Hole Saw Like a Pro (DIYer)

How to use a hole saw without breaking your wrist

Hole Saw Tip (how to make a hole Larger) #shorts

How To Cut PERFECTLY CIRCULAR HOLES! (Hole Saw Bit/Circle Bit--Cut Circles in Wood, Drywall, PVC!)

Комментарии

0:04:10

0:04:10

0:02:57

0:02:57

0:00:38

0:00:38

0:02:23

0:02:23

0:08:10

0:08:10

0:08:55

0:08:55

0:04:01

0:04:01

0:15:12

0:15:12

0:00:23

0:00:23

0:02:01

0:02:01

0:05:41

0:05:41

0:00:34

0:00:34

0:00:53

0:00:53

0:13:21

0:13:21

0:06:08

0:06:08

0:04:25

0:04:25

0:00:59

0:00:59

0:02:50

0:02:50

0:20:45

0:20:45

0:00:27

0:00:27

0:11:01

0:11:01

0:07:53

0:07:53

0:00:26

0:00:26

0:04:40

0:04:40