filmov

tv

BEST WAY to Harden Leather?

Показать описание

We have made leather armor but, so far, haven't taken that extra step into hardening leather. How DO you harden leather? What is the best method to use to harden leather? Does harden leather really work? We find all that out and MORE on today's episode. Stay Tuned!

Join us at Conquest!

The Dendronia Discord Server

Firebrand productions (the one who made my sword!)

---------------------------------------------------------------

--------------------------------------------------------------

🌳 Support and Contact!

📫 Skill Tree Mailing Address:

Skill Tree

9 Cornerstone Square, Suite 335

Westford, MA 01886

--------------------------------------------------------------

Links in the description may be affiliate links, which would give us a commission if you use them.

BEST WAY to Harden Leather?

The Leather Element: Hardening Leather

How to Wet Form Leather // Three Easy Techniques

The Leather Element: Wet Molding Leather

BURNISHING LEATHER (HOW TO) - finish edges of leather tutorial

How to Harden Leather Armor with Water

How to finish 'FUZZY' side of vegetable tan leather

FINALLY! A Better Way To Restore Leather

Ultimate Guide To Restoring Leather Boots // Back To Life In 4 Mins

Fix Wrinkled Leather | how to harden leather | nyc

The Leather Element: Simple Mistakes to Avoid in Leathercraft

How to Make Armour - Leather Vambraces

RUINED? How To Fix Over Conditioned Leather Boots

Choosing the Correct Leather for Your Project (Made Easy)

How Not To Break Your Shin by Bas Rutten

Special Operations Preparation - Foot Care

How to Hand Stitch Leather - Saddle Stitch Tutorial, Beginner Leatherwork

How to Hand Stitch Leather: Get Better, Fast!

Hardened Super Wood! - Can It Rival Steel?

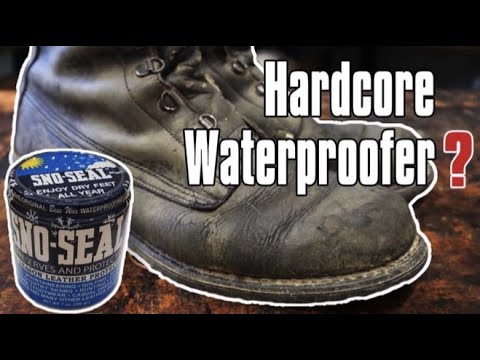

WATERPROOF Your Leather | One of the BEST Products We Use

How to Make Bioplastic

Housekeeping Tips : How to Wash a Leather Jacket

Heat Gun Vs Hair Dryer - How To Properly Use Heat Gun On Leather - LeatherSeats.com

A 5000 year old wood finish formula that can't be messed up!

Комментарии

0:34:42

0:34:42

0:05:16

0:05:16

0:06:11

0:06:11

0:08:52

0:08:52

0:04:05

0:04:05

0:20:43

0:20:43

0:09:43

0:09:43

0:19:49

0:19:49

0:04:00

0:04:00

0:03:26

0:03:26

0:09:04

0:09:04

0:18:45

0:18:45

0:10:15

0:10:15

0:06:45

0:06:45

0:01:59

0:01:59

0:01:51

0:01:51

0:10:55

0:10:55

0:16:12

0:16:12

0:15:10

0:15:10

0:07:35

0:07:35

0:00:29

0:00:29

0:01:58

0:01:58

0:05:00

0:05:00

0:06:21

0:06:21