filmov

tv

Capacitor Test under Load 3D

Показать описание

In this 3D animation, Bryan Orr with HVAC School explains how to test a run capacitor properly while the HVAC system is under load. He covers the importance of capacitors for motor efficiency and reliability.

This video provides a step-by-step process for testing capacitors under load using a multimeter to measure amperage and voltage. Bryan shares the formula to calculate microfarads and explains what capacitor readings indicate a need for replacement. This easy-to-follow tutorial is useful for both maintenance and service calls.

Bryan emphasizes safety and meter accuracy as critical factors. He also mentions the free under-load capacitor testing calculator available in the HVAC School mobile app. Whether you're a beginner or a seasoned technician, this 3D video provides valuable tips for assessing capacitor performance. Check out HVAC School for more in-depth training!

This video provides a step-by-step process for testing capacitors under load using a multimeter to measure amperage and voltage. Bryan shares the formula to calculate microfarads and explains what capacitor readings indicate a need for replacement. This easy-to-follow tutorial is useful for both maintenance and service calls.

Bryan emphasizes safety and meter accuracy as critical factors. He also mentions the free under-load capacitor testing calculator available in the HVAC School mobile app. Whether you're a beginner or a seasoned technician, this 3D video provides valuable tips for assessing capacitor performance. Check out HVAC School for more in-depth training!

Capacitor Test under Load 3D

Capacitor Test under Load 3D animation of air conditioner in Hindi Urdu #technology #cool #hvac

capacitors|3d animation #shorts #capacitor

Capacitors Explained - The basics how capacitors work working principle

Run Capacitor Fundamentals Class

What is a capacitor? #technology #electronics #engineering

What is Start Capacitor? | Animation | HVAC | Electrical

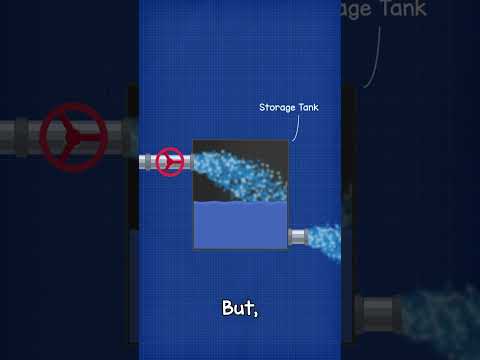

Why do Capacitors allow AC, but block DC?

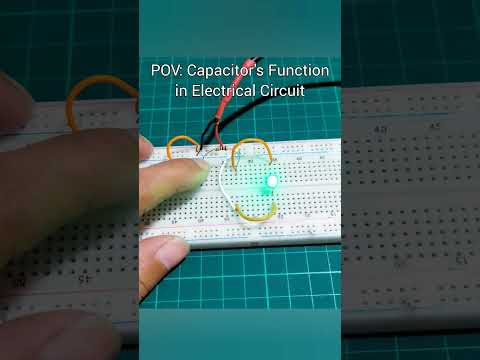

What does a capacitor do?

How Capacitors Work

Was I WRONG? Can a Capacitor FAIL with HIGH MFD?

Capacitor Charge Discharge Test In Megger Meter

Start Capacitors & Run Capacitors for Electric Motors - Differences Explained by TEMCo

Residential AC Faulty Dual Run Capacitor [HVAC Training 2019]

How Capacitor Works #electronics #capacitor

How To Check & Replace An Air Conditioner Capacitor

How does a capacitor work ??

super capacitor disassembly

[2019 Guide] How to Diagnose a Faulty Start Capacitor (on a Heat Pump)

Run Capacitor Facts You May Not Know

Single phase Induction Motor / Capacitor start capacitor run motor / Best video for you to learn.!😍💪...

this is not a GPU #shorts

Capacitor tower

Basic Voltage and Safety Measurements on an Air Conditioner

Комментарии

0:04:07

0:04:07

0:03:27

0:03:27

0:00:42

0:00:42

0:08:42

0:08:42

0:13:57

0:13:57

0:00:54

0:00:54

0:04:31

0:04:31

0:02:06

0:02:06

0:01:23

0:01:23

0:03:33

0:03:33

0:04:19

0:04:19

0:00:21

0:00:21

0:07:21

0:07:21

0:05:37

0:05:37

0:00:16

0:00:16

0:08:52

0:08:52

0:09:23

0:09:23

0:00:16

0:00:16

![[2019 Guide] How](https://i.ytimg.com/vi/7fdg_JIdhj8/hqdefault.jpg) 0:05:25

0:05:25

0:36:16

0:36:16

0:07:52

0:07:52

0:00:29

0:00:29

0:01:00

0:01:00

0:07:51

0:07:51