filmov

tv

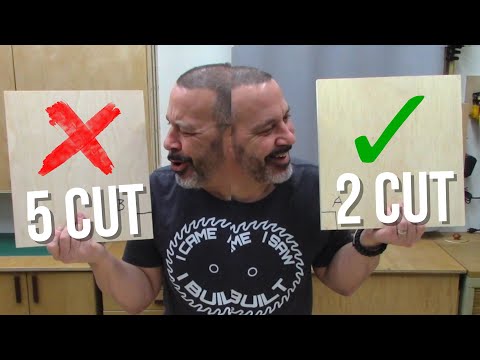

the FLAW with Ultimate crosscut sleds

Показать описание

PANEL SLED PLANS:

FULL ARTICLE:

To be a little more exact with the five-cut method simplification:

1. The test board needs to be square.

2. The size of the test board needs to be the same as the distance between the two screws (one screw is the pivot, one screw is likely near the end of the fence)

3. The pivot point needs to be as close to the blade as possible (1" should do).

US & CANADIAN AFFILIATE LINKS

PROJECT PARTS:

DOWELMAX:

DOWELMAX 3/8" Kit:

DOWELMAX 1/2" Expansion:

BLADES:

TOOLS:

BITS:

SUPPLIES

INSTAGRAM:

MUSIC:

Epidemic Sound

Use my referral link and start your free 30-day trial:

FULL ARTICLE:

To be a little more exact with the five-cut method simplification:

1. The test board needs to be square.

2. The size of the test board needs to be the same as the distance between the two screws (one screw is the pivot, one screw is likely near the end of the fence)

3. The pivot point needs to be as close to the blade as possible (1" should do).

US & CANADIAN AFFILIATE LINKS

PROJECT PARTS:

DOWELMAX:

DOWELMAX 3/8" Kit:

DOWELMAX 1/2" Expansion:

BLADES:

TOOLS:

BITS:

SUPPLIES

INSTAGRAM:

MUSIC:

Epidemic Sound

Use my referral link and start your free 30-day trial:

the FLAW with Ultimate crosscut sleds

The EASY Ultimate Table Saw Sled

Crosscut Sled One Rail vs Two Rail - Which is better for Woodworking at the Tablesaw? 1 or 2 Runner

TCS-200 Professional Crosscut Sled

your crosscut sled is way too big

Two Minute Build | Easiest Table Saw Crosscut Sled

The ULTIMATE crosscut sled for 2024 (DIY)

Worlds Nicest Table Saw Sled || Ultimate Table Saw Upgrade

Flagship Table Saw Sled! Crosscut, Miter, Bevel, Dado, Picture Frames & More!

How to Build a Table Saw Sled || Table Saw Cross Cut Sled

How to Make a Cross-Cut Sled with an Adjustable Fence

How to Make a Table Saw Sled with Handles for Added Safety

3 Cut Method to a Dead-on Crosscut Sled with Tom McLaughlin

DO NOT use 5 cut method for table saw sled.

Multi-Function Crosscut - Miter - Dado - Bevel - Tenon Cutting - Picture Frame Table Saw Sled!

Have a Table Saw? You NEED to do This!!!

Best Cross-Cut Sled Ever??..

Build the ultimate table saw sled, FAST with the New and Improved ZeroPlay 360 Sled Kit!

Patriotic Cross Cut Sled, X sled version

An old machinist's tool that woodworkers are snatching up!

Small Crosscut Sled for Table Saw DWE7491RS

Box Joinery Technique Using Crosscut Sled for Table Saw

How to Make a Cross Cut Sled

Crosscut Tips and Strategies

Комментарии

0:20:44

0:20:44

0:08:03

0:08:03

0:07:28

0:07:28

0:02:28

0:02:28

0:12:59

0:12:59

0:02:19

0:02:19

0:04:02

0:04:02

0:33:30

0:33:30

1:10:44

1:10:44

0:25:46

0:25:46

0:15:07

0:15:07

0:12:01

0:12:01

0:21:13

0:21:13

0:13:03

0:13:03

0:40:26

0:40:26

0:15:57

0:15:57

0:22:17

0:22:17

0:08:26

0:08:26

0:30:11

0:30:11

0:06:14

0:06:14

0:09:46

0:09:46

0:03:46

0:03:46

0:41:07

0:41:07

0:16:11

0:16:11