filmov

tv

2. How do you make 10 frame bee hives from RECYCLED PALLETS?

Показать описание

In this episode, Paul makes 10 frame bee hives from recycled timber pallets.

There's not a lot to it really, Select some pallets, tear them apart, cut them to size then nail and glue them together to make a bee hive.

We hope you enjoy the video as much as we enjoy making them.

B,P & C

There's not a lot to it really, Select some pallets, tear them apart, cut them to size then nail and glue them together to make a bee hive.

We hope you enjoy the video as much as we enjoy making them.

B,P & C

How To Make 2 Ingredients Slime At Home, Satisfied Crush Edition

iOS 18.2.1 - Do This IMMEDIATELY After You Update!

2 Minutes Maggi | How to make plain maggi? | Easy and Tasty | the crazyfoodmile | #shorts | #beta

Stop Throwing Away Orange Peel! Make the Fondest Snack (Only 2 Ingredients)

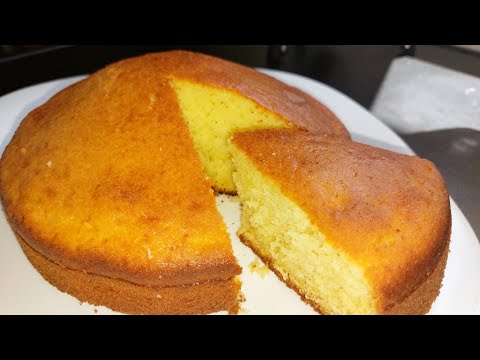

cake in 2 minutes! you will make this cake every day! easy and quick to prepare

2 Hot Glue Gun DIYs You Can Make In 16 Seconds #shorts

How to Make 2 Discord Accounts from 1 Email Address #Shorts

Sunny Side Up Eggs 2 Ways! (How To Make Perfect Sunny Side Up Eggs)

Even More Small Details You Missed In Squid Game Season 2

How To Make Brown Sugar (2 Ingredients)

Homemade grape wine 🍷 Let’s make some 2 ingredients grape wine: 🍇 + sugar~

How to make Homemade Whipping Cream in 2 Minutes

Squid Game Season 2 on Roblox!

Make TOFU at HOME with just 2 Ingredients!

2 INGREDIENTS SLIME!! How to make Flour and Sugar Fluffy Slime without borax and glue

How to Make Plant Fertilizer with 2 Natural Ingredients | creative explained

How to make best Nescafe coffee in just 2 minutes | Instant Coffee | Hot Coffee recipe

If you have 1 cup of oats and 2 eggs, make this 5 minutes recipe for breakfast

How to Make Cheese at Home - 2 ingredient Easy Cheese Recipe

2 Easy ways to make Fufu

If you have 1 banana and 2 eggs, make this 5 minutes recipe for breakfast

You Won't Believe What You Can Make With Just 2 Ingredients! So Yummy

How to Make Mozzarella Cheese 2 Ingredients Without Rennet | Homemade Cheese Recipe

3 REAL Ways To Get FREE ROBUX.. (2024)

Комментарии

0:00:10

0:00:10

0:05:07

0:05:07

0:00:29

0:00:29

0:00:57

0:00:57

0:03:37

0:03:37

0:00:17

0:00:17

0:00:20

0:00:20

0:00:51

0:00:51

0:14:05

0:14:05

0:00:26

0:00:26

0:00:59

0:00:59

0:00:16

0:00:16

0:17:52

0:17:52

0:04:59

0:04:59

0:02:57

0:02:57

0:00:43

0:00:43

0:00:25

0:00:25

0:03:36

0:03:36

0:03:13

0:03:13

0:06:49

0:06:49

0:02:46

0:02:46

0:12:49

0:12:49

0:12:15

0:12:15

0:06:47

0:06:47