filmov

tv

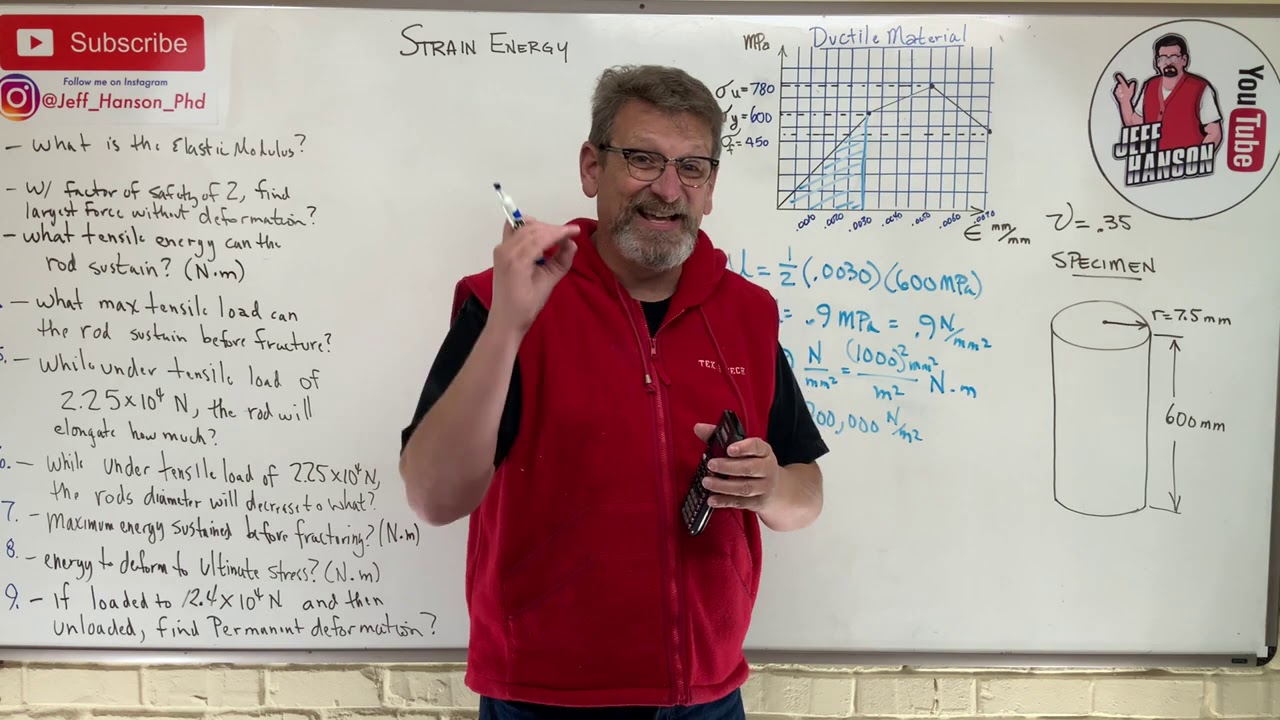

Mechanics of Materials: Lesson 12 - Strain Energy; Example Problems From Stress Strain Diagram

Показать описание

Top 15 Items Every Engineering Student Should Have!

This video is NOT sponsored. Some product links are affiliate links which mean if you buy something we'll receive a small commission.

Please consider supporting the channel by subscribing, commenting, and liking each video. This moves these videos up the search list and helps me greatly. Thank you for watching.

This video is copyrighted by the Jeff Hanson for the private use of our audience. Any other use of this video or any pictures, descriptions, or accounts of the video without written consent from Jeff Hanson is strictly prohibited.

Mechanics of Materials: Lesson 12 - Strain Energy; Example Problems From Stress Strain Diagram

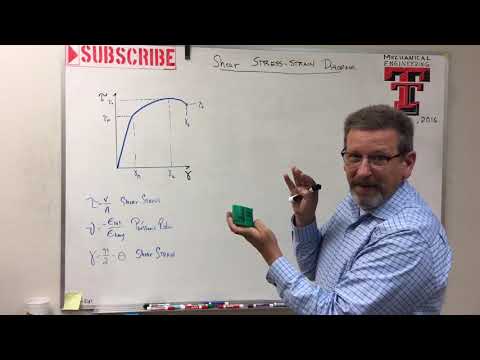

Mechanics of Materials: Lesson 12 - Shear Stress-Strain Diagram

Mechanic of Materials: Lesson 24 -- Power Transmission Torque Example

Mechanics of Materials: Lesson 23 - Shear Stress Due to Torsion, Polar Moment of Inertia

Mechanics of Materials: Lesson 13 - Stress Strain Diagram Example Problem

Mechanics of Materials: Lesson 7 - Intro to Strain and Poisson’s Ratio

Mechanics of Materials: Lesson 25 - Angle of Twist Due to Torque, Torsion

Tensile Stress & Strain, Compressive Stress & Shear Stress - Basic Introduction

BEGINNER COURSE IN AUTOCAD MECHANICAL - EPISODE 12

Mechanics of Materials: Lesson 38 - Maximum Transverse Shear Stress in a Beam

Mechanics of Materials: Lesson 21 - Thermal Coefficient of Expansion, Axial Elongation

Mechanics of Materials: Lesson 18 - Axial Elongation Example Problem, Displacement

Mechanics of Materials: Lesson 17 - Axial Elongation Due to Axial Load Example

Mechanics of Materials: Lesson 11 - Modulus of Elasticity Example Problem

Elasticity & Hooke's Law - Intro to Young's Modulus, Stress & Strain, Elastic &...

Mechanics of Materials: Lesson 66 - Intro to Column Buckling

Mechanics of Materials: Lesson 37 - What the Heck is Q? Example Problem

Mechanics of Materials: Lesson 15 - Shear Stress Strain Diagram

Mechanics of Materials: Lesson 31 - The Flexure Formula, Beam Bending Example

Mechanics of Materials: Lesson 8 - Shear Strain Explained, Sign Convention

Mechanics of Materials: Lesson 62 - Slope and Deflection Beam Bending Introduction

Mechanics of Materials: Lesson 39 - Shear Flow Introduction, Example Problem

Understanding and Analysing Trusses

Mechanics of Materials: Lesson 9 - Stress Strain Diagram, Guaranteed for Exam 1!

Комментарии

0:43:02

0:43:02

0:08:06

0:08:06

0:16:14

0:16:14

0:17:01

0:17:01

0:19:03

0:19:03

0:16:02

0:16:02

0:17:47

0:17:47

0:13:05

0:13:05

0:04:09

0:04:09

0:17:06

0:17:06

0:20:18

0:20:18

0:15:41

0:15:41

0:11:48

0:11:48

0:18:48

0:18:48

0:19:01

0:19:01

0:20:06

0:20:06

0:18:03

0:18:03

0:08:30

0:08:30

0:15:25

0:15:25

0:15:38

0:15:38

0:17:57

0:17:57

0:12:13

0:12:13

0:17:41

0:17:41

0:22:41

0:22:41