filmov

tv

Liquid Metal Cooling a PHONE!?!?!

Показать описание

It's a really bad idea to put Liquid Metal in your phone - so we're going to try it.

Buy Liquid Metal:

Intro Screen Music Credit:

Title: Laszlo - Supernova

Buy Liquid Metal:

Intro Screen Music Credit:

Title: Laszlo - Supernova

The Smartphone from 2040 has a 'Liquid Metal' cooling system inside?

The First Phone With Liquid Metal Cooling | It this the future of smarphones?

Liquid Metal Cooling a PHONE!?!?!

PS4 Pro Liquid Metal vs Thermal Paste

Ultimate Guide to Applying Liquid Metal to Your CPU, Laptop, GPU, and Game Console

Phone Cooling SelfAdhesive Plate Mobile Gaming Live Stream Heat Dissipation Vapor Chamber Technology

isn't liquid metal thermal paste dangerous? #shorts

Can liquid metal thermal paste destroy a cpu cooler? #shorts

Iphone made of liquid metal #shorts

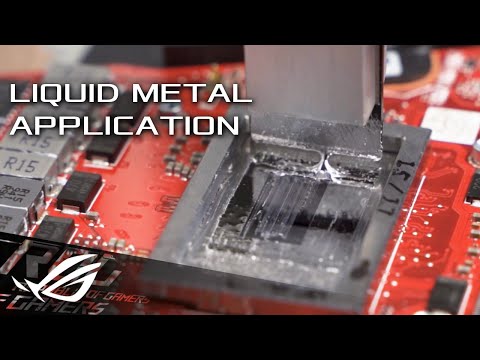

Liquid Metal Technology | ROG

the future of thermal paste technology #shorts

What's The Best Thermal Paste?! | Comparing Arctic, Gelid & Thermal Grizzly

Worlds most Complicated smartphone cooling system - (ROG Phone 7 Ultimate)

IPHONE was filled with liquid metal #science #experiment

What Does Liquid Metal Look like After 3 Months Inside a MacBook Pro?

The Truth about the PS5's Liquid Metal Issue

Mixing liquid metal and thermal paste #experiment #pc #thermal #gaming #shorts

thermal grizzly conductonaut liquid metal thermal paste 1g 5g

Liquid Metal Application

Introducing Loop LiquidCool Technology

How to apply Thermal Paste and Liquid Metal #shorts #howto

Overheating PS5 ? Replace your Liquid metal thermal paste #repair #liquidmetal #overheatingps5

iPhone 15 Spigen Liquid Air Back Cover Unboxing #shorts

Liquid Metal + Threadripper! Will It Make A Difference?

Комментарии

0:08:08

0:08:08

0:00:52

0:00:52

0:08:42

0:08:42

0:04:07

0:04:07

0:18:21

0:18:21

0:00:25

0:00:25

0:00:16

0:00:16

0:00:40

0:00:40

0:00:15

0:00:15

0:00:53

0:00:53

0:01:00

0:01:00

0:00:39

0:00:39

0:09:49

0:09:49

0:00:20

0:00:20

0:06:59

0:06:59

0:00:58

0:00:58

0:00:35

0:00:35

0:00:10

0:00:10

0:00:57

0:00:57

0:01:01

0:01:01

0:00:45

0:00:45

0:00:24

0:00:24

0:00:18

0:00:18

0:15:14

0:15:14