filmov

tv

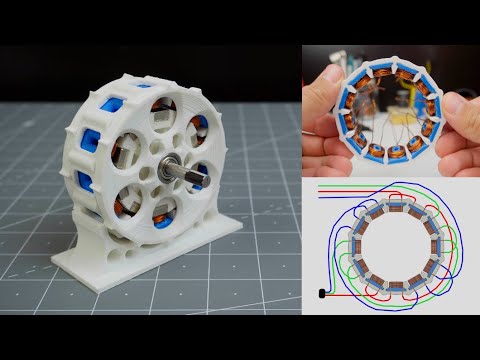

A HUGE 3D Printed Brushless Motor??? How Much Thrust Can It Make?

Показать описание

Hope you guys enjoyed the video! This thing was really fun to make and test. A bit scary too. Nevertheless, it was a cool project, and I would love to do more with the motor in the future. Let me know if you have any ideas.

@ChristophLaimer:

Get Files for Motor:

Instructables Article:

Follow me for more updates on projects:

FliteTest Video:

Links to stuff I use (affiliate links):

A HUGE 3D Printed Brushless Motor??? How Much Thrust Can It Make?

3D Printed HUGE Brushless Motor | I've made Cristoph Laimer's motor

Is 3D Printing a motor possible? (Experiment)

How This 7000W Motor Was NOT Powerful Enough!

3D printed Brushless Motor

makeSEA 3D Printed Brushless Motor - Version 1

First run of large 3d-printed brushless Motor

UAV - 3D Printed brushless motor Iridesign

Weekly Recap! Ep.24! We are making the ULTIMATE UNIMOG!

How to make a big powerful Brushless motor | DIY 3D Printed Brushless ESC motor 2020

800w 3D printed brushless motor

3D printed brushless quadruped.

Is This The Fastest 3D Printed Brushless Motor / Drone Motor

How to make an extrem high speed 3D printed ESC brushless motor

How to Make a Brushless Motor / 3D Printed Brushless Motor

Worth The Price? Creality Ender 3 S1 3d Printer Review

The Mostly Printed 3D Printer! #MRRF2022

3D printed brushless motor - iridesign open source controller

Waterproof 3D Printed Brushless Motor... Will it work?

Making 3D printed Brushless Motor ( DIY Brushless Motor )

3d Printed Brushless Motor

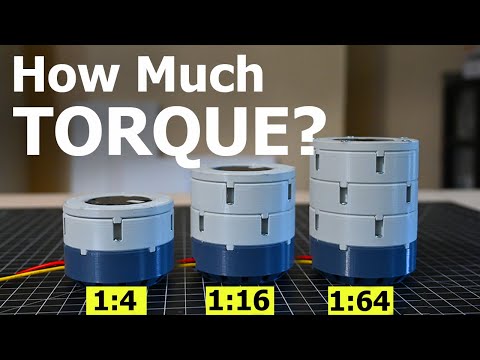

3D Printed Stackable BRUSHLESS Motor Gearbox

The Anycubic Vyper 3d Printer Is SERIOUSLY Impressive

3D Printed Brushless Motor #DC Motor #shorts

Комментарии

0:08:08

0:08:08

0:16:04

0:16:04

0:10:21

0:10:21

0:12:06

0:12:06

0:00:31

0:00:31

0:00:24

0:00:24

0:00:50

0:00:50

0:00:43

0:00:43

0:10:56

0:10:56

0:11:23

0:11:23

0:01:36

0:01:36

0:00:13

0:00:13

0:07:18

0:07:18

0:17:06

0:17:06

0:07:11

0:07:11

0:21:29

0:21:29

0:04:06

0:04:06

0:00:49

0:00:49

0:12:17

0:12:17

0:00:37

0:00:37

0:00:47

0:00:47

0:08:26

0:08:26

0:23:18

0:23:18

0:00:48

0:00:48