filmov

tv

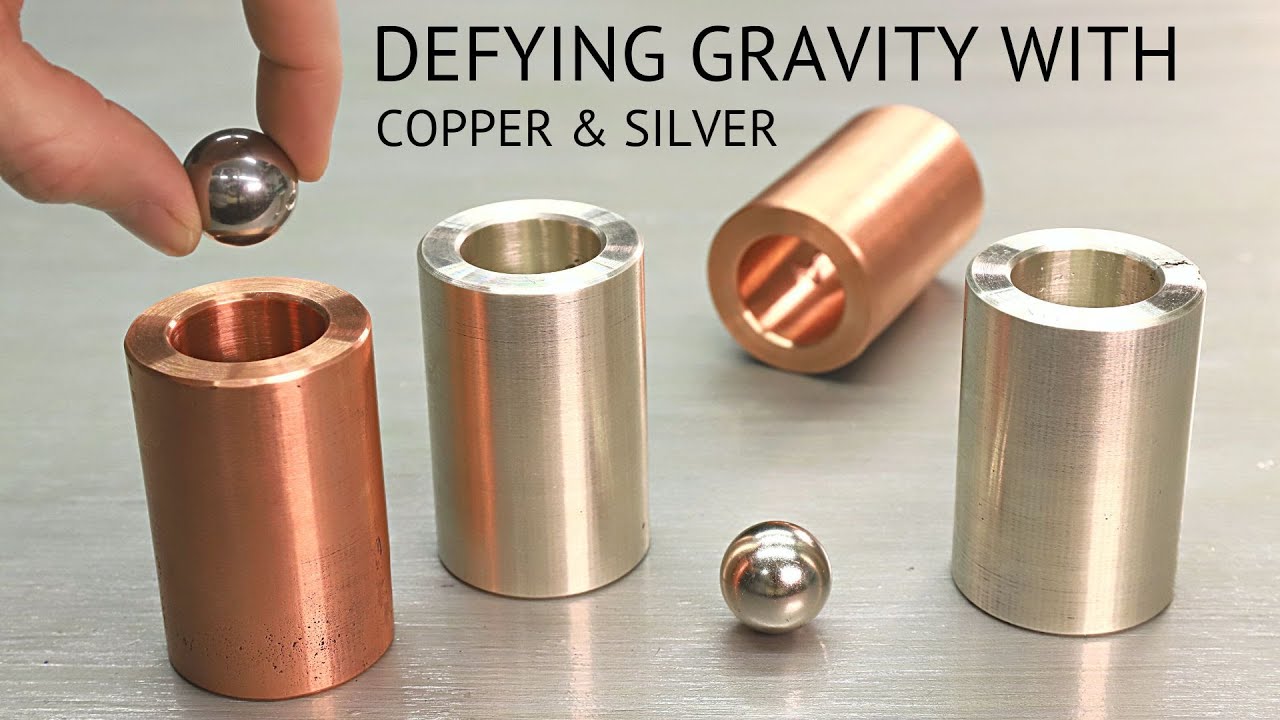

Making Anti-gravity tubes - Copper & Silver! - Lenz's law - Metal casting Experiment

Показать описание

In this video I will be making a set of silver and copper tubes to experiment with Lenz's law.

Casting equipment

3d printing FDM

3d printing Resin

Belt Grinder

Belt Grinder Accessories

Welding

Metal finishing tools

General

Some of my favorite tools of the year

Camera Equipment

All of the links above are affiliate links. This means that, at zero cost to you, I will earn an affiliate commission if you click through the link and finalize a purchase.

Casting equipment

3d printing FDM

3d printing Resin

Belt Grinder

Belt Grinder Accessories

Welding

Metal finishing tools

General

Some of my favorite tools of the year

Camera Equipment

All of the links above are affiliate links. This means that, at zero cost to you, I will earn an affiliate commission if you click through the link and finalize a purchase.

Making Anti-gravity tubes - Copper & Silver! - Lenz's law - Metal casting Experiment

A genuine 'Anti-Gravity' device and how to build it

Defying Gravity - HUGE Neodymium Magnet vs Copper Tube Experiment - The Power of Lenz's Law!

Impossible Antigravity

anti-gravity project

How Viktor Grebennikov Built an Anti Gravity Levitating Machine | UFO patents & Anti-Gravity

Anti-Gravity Experiment 01 - Neodymium Magnets at 13000RPM

Vimana mercury vortex engine

Antigravity - How to make magnetic levitation device at home DIY

Antigravity structure with Magnets #shorts

Liquid Mercury vortex in a magnetic field

Viktor Grebennikov - Anti-Gravity & Levitation

I Slowed Down Gravity Using Copper Pipe || Lenz Law Experiment || Anti-Gravity || Free Energy

Making Electrets for Antigravity and other Experiments

Anti-Gravity

Make a zero gravity triangle from copper thread

Homemade Cyclotron

Eddy Current Magnet Copper Pipe Anti-gravity

selfrunning magnet motor powering loads and is accelerating #shorts

Magnetic 'Antigravity' with copper and a magnet.

HV DC Antigravity Lifter Test

Tensegrity 2.0 Copper Pipe Structure

Magnetic induction heating with infrared camera | Magnetic Games

How to Make: Anti Gravity Chamber

Комментарии

0:11:21

0:11:21

0:17:57

0:17:57

0:10:22

0:10:22

0:03:48

0:03:48

0:10:25

0:10:25

0:15:31

0:15:31

0:02:08

0:02:08

0:01:22

0:01:22

0:01:55

0:01:55

0:00:53

0:00:53

0:03:46

0:03:46

0:05:47

0:05:47

0:05:02

0:05:02

0:08:50

0:08:50

0:00:21

0:00:21

0:04:49

0:04:49

0:00:28

0:00:28

0:00:07

0:00:07

0:00:15

0:00:15

0:00:10

0:00:10

0:01:44

0:01:44

0:05:26

0:05:26

0:03:10

0:03:10

0:01:47

0:01:47