filmov

tv

Motorcycle Carburetor Working Principle and Animation

Показать описание

How carburetor works ?

Carburetor is used to mix gasoline into the intake air flow with ideal volume, and proper timming.

But how does it work?

Carburetor works by utilizing pressure differences. When air flows, the air pressure is lower than the atmospheric pressure.

This is called the bernoulli principle.

This principle states that the faster the air flow, the lower the air pressure.

Due to this pressure drop, gasoline is able to be sucked into the air stream.

But to get faster air flow, we need to add venturi in the middle of the air hose.

Venturi is a section of air hose with a smaller diameter. Its function is to accelerate the air flow.

So according to Bernoulli's law, air pressure can be even smaller. It makes gasoline more easily sucked into the air stream.

So, the carburetor uses the Bernoulli principle to mix gasoline into the air stream towards the intake manifold.

But how does the carburetor control the engine rpm?

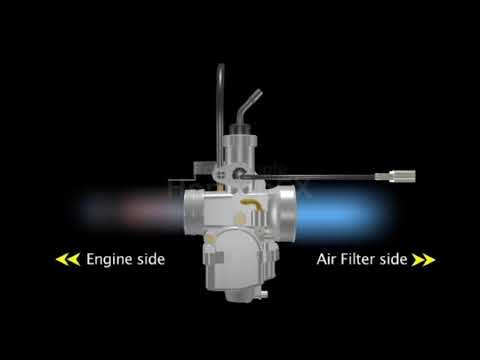

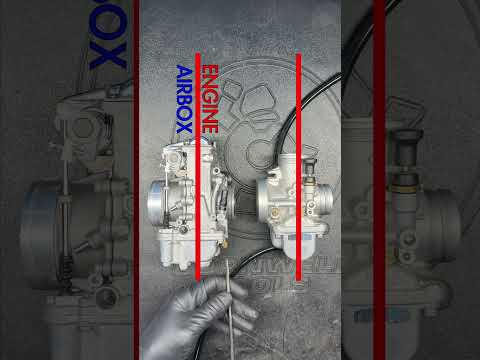

Please see the anatomy of this carburetor.

This is a variable venturi carburetor.

In this type, controlling rpm is done by adjusting the width of the venturi.

So before we go on, we should know some important parts of this carburetor.

So when the engine is idle, the piston is in the lowest position. It makes the venturi very narrow. And the main jet is also covered by needle jet.

This condition forces air to flow through the idle air channel and fuel out through the pilot jet.

When we pull the rpm handle, the piston is lifted. This makes the venturi wider and main jet is open.

So that, greater air volume flow through the venturi and fuel also sucked through the main jet.

The higher the piston position, the wider venturi will be. The wider the venturi, the greater the air flow. So that the result, the faster engine RPM.

Then, we know that the fuel tank is higher than the carburetor. Why fuel doesn't overflow?

Apparently, there is a float system that makes the fuel does not overflow.

This system only utilizes float movement to close the fuel from the tank.

So when the fuel in the float chamber is empty, the float goes down and the float needle is open.

That makes gasoline fill the float chamber.

When the gasoline is full, the float rises and the needle also closes the fuel.

So there is no fuel flow to the float chamber. This makes the gasoline does not overflow.

When the gasoline in the float chamber decreases, the float drops and the gasoline returns to fill the float chamber.

And the last, you must be confused by the screws on the side of carburetor.

The screws are used to control the idle rpm.

First idle air screw. It is used to adjust the width of the idle air channel. So when it tighten, the idle air channel becomes narrower so that less air passes through.

Second piston screw. That will adjust the height of the piston when idle. If it is tightened, the piston is lifted and that makes more air flow via venturi.

Carburetor is used to mix gasoline into the intake air flow with ideal volume, and proper timming.

But how does it work?

Carburetor works by utilizing pressure differences. When air flows, the air pressure is lower than the atmospheric pressure.

This is called the bernoulli principle.

This principle states that the faster the air flow, the lower the air pressure.

Due to this pressure drop, gasoline is able to be sucked into the air stream.

But to get faster air flow, we need to add venturi in the middle of the air hose.

Venturi is a section of air hose with a smaller diameter. Its function is to accelerate the air flow.

So according to Bernoulli's law, air pressure can be even smaller. It makes gasoline more easily sucked into the air stream.

So, the carburetor uses the Bernoulli principle to mix gasoline into the air stream towards the intake manifold.

But how does the carburetor control the engine rpm?

Please see the anatomy of this carburetor.

This is a variable venturi carburetor.

In this type, controlling rpm is done by adjusting the width of the venturi.

So before we go on, we should know some important parts of this carburetor.

So when the engine is idle, the piston is in the lowest position. It makes the venturi very narrow. And the main jet is also covered by needle jet.

This condition forces air to flow through the idle air channel and fuel out through the pilot jet.

When we pull the rpm handle, the piston is lifted. This makes the venturi wider and main jet is open.

So that, greater air volume flow through the venturi and fuel also sucked through the main jet.

The higher the piston position, the wider venturi will be. The wider the venturi, the greater the air flow. So that the result, the faster engine RPM.

Then, we know that the fuel tank is higher than the carburetor. Why fuel doesn't overflow?

Apparently, there is a float system that makes the fuel does not overflow.

This system only utilizes float movement to close the fuel from the tank.

So when the fuel in the float chamber is empty, the float goes down and the float needle is open.

That makes gasoline fill the float chamber.

When the gasoline is full, the float rises and the needle also closes the fuel.

So there is no fuel flow to the float chamber. This makes the gasoline does not overflow.

When the gasoline in the float chamber decreases, the float drops and the gasoline returns to fill the float chamber.

And the last, you must be confused by the screws on the side of carburetor.

The screws are used to control the idle rpm.

First idle air screw. It is used to adjust the width of the idle air channel. So when it tighten, the idle air channel becomes narrower so that less air passes through.

Second piston screw. That will adjust the height of the piston when idle. If it is tightened, the piston is lifted and that makes more air flow via venturi.

Комментарии

0:04:44

0:04:44

0:02:38

0:02:38

0:04:52

0:04:52

0:03:24

0:03:24

0:38:36

0:38:36

0:07:52

0:07:52

0:24:38

0:24:38

0:00:18

0:00:18

0:04:51

0:04:51

0:10:01

0:10:01

0:01:00

0:01:00

0:13:31

0:13:31

0:04:44

0:04:44

0:05:43

0:05:43

0:04:44

0:04:44

0:00:28

0:00:28

0:03:33

0:03:33

0:01:09

0:01:09

0:22:42

0:22:42

0:04:29

0:04:29

0:13:51

0:13:51

0:05:38

0:05:38

0:00:33

0:00:33

0:04:29

0:04:29