filmov

tv

E3D made an impressive HIGH FLOW nozzle!

Показать описание

E3D finally released their new High Flow nozzle where they partnered up with Bondtech and their Core Heating Technology. But at almost $50 is it even any good?

*Get Revo High Flow (affiliate)*

*Other High Flow Options (affiliate)*

💚 Support me 💚

Join as a YouTube member!

📚 Further information:

⚙ My gear:

🎥 CAMERAS & LENSES

🎙AUDIO

🔴 LIVE STREAMING

Chapters

00:00 Introduction

01:40 Revo High Flow

03:31 Video Sponsor

05:10 Revo to V6 Adapter

05:45 Flow Tests

08:16 Blobb Test

08:46 60 W Heater Core

12:54 Print Quality

13:40 Conclusion

#3Dprinting #RevoHighFlow #CNCKitchen

DISCLAIMER: Part of this video was sponsored by Skillshare.

FTC Disclaimer: A percentage of sales is made through Affiliate links

E3D made an impressive HIGH FLOW nozzle!

Testing E3D's new Revo High Flow nozzle to its limits!

E3D Revo High Flow Düsen getestet!

E3D Revo practical review: Fast coreXY 3D printing?

E3D Revo™ is great BUT has a dirty secret! (REVIEW)

Fast 3D printing is bad for Strength! (and how to fix it!)

Impressive 3D Printing Technology at FORMNEXT 2022

10 Secret 3D Printing Tricks Only Experts Know...

Best 3D Printer 2024 - Top 3D Printers That Every Enthusiast Must Have!

Impressive 4-Axis Non-Planar 3D Printing

Testing the ObXidian nozzle and new E3D Revo developments

3D Printing an INSANE Steel Part that's IMPOSSIBLE to Make on a CNC Machine

How Concrete Homes Are Built With A 3D Printer | Insider Art

MICRO 3D Printing with a 0.1 mm nozzle

E3D’s Rapidchange Revo-lution?

The Collab We've All Been Waiting For!! - Diamondback and E3D, ERRF 2023

Top 5 Fun and Useful Projects to 3D Print

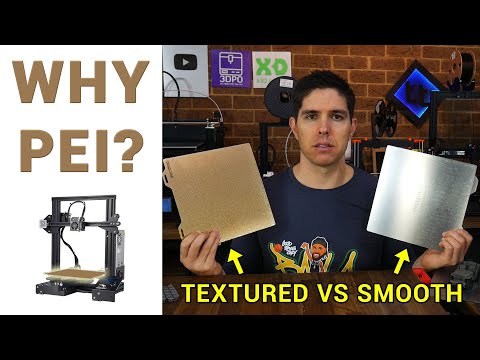

Guide to PEI 3D printer beds: Why and when to use smooth vs textured

3D Printer Blobs: a mysterious problem you won't guess how to fix 🤔

Who says one nozzle is enough!? 3D printing with different nozzle sizes

Impressive Compliant Mechanism 3D Printed on the Fuse 1

10 Amazing 3D Printed Objects

Amazing 3D printed dragon ASMR bed removal

50+ Useful 3D Prints You Never Knew You Could Print

Комментарии

0:16:25

0:16:25

0:23:57

0:23:57

0:05:54

0:05:54

0:15:19

0:15:19

0:22:22

0:22:22

0:15:11

0:15:11

0:11:45

0:11:45

0:04:35

0:04:35

0:09:57

0:09:57

0:14:07

0:14:07

0:14:03

0:14:03

0:02:48

0:02:48

0:05:33

0:05:33

0:14:11

0:14:11

0:23:47

0:23:47

0:12:37

0:12:37

0:09:41

0:09:41

0:13:30

0:13:30

0:08:27

0:08:27

0:00:28

0:00:28

0:00:06

0:00:06

0:07:23

0:07:23

0:00:24

0:00:24

0:24:02

0:24:02