filmov

tv

Matching Non Nominal Metric Threads (Internal/External)

Показать описание

Continuing the series "Threading on an Import Lathe", this video will focus on matching a non-nominal metric thread. Links to other videos in this series below:

Part 4 - Matching Non-Nominal Imperial Threads

Part 5 - Metric Threading on Imperial Lathe

Part 4 - Matching Non-Nominal Imperial Threads

Part 5 - Metric Threading on Imperial Lathe

Matching Non Nominal Metric Threads (Internal/External)

Matching Non Nominal Imperial Threads (Internal/External)

How to Make Threading Calculation|| Metric thread Calculation Without Chart💥💥💥😲😲😲

Metric External Threading On Imperial Import Lathe

How to Identify Thread Pitch and Size | Tech Tips | Swagelok [2020]

How Metric Bolts are Measured

How to Determine the hole size for an Internal Thread -- SHOP GEM !!

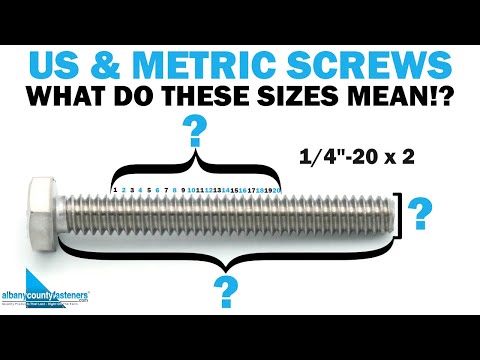

How to Measure Screws & Bolts - US & Metric Sizing | Fasteners 101

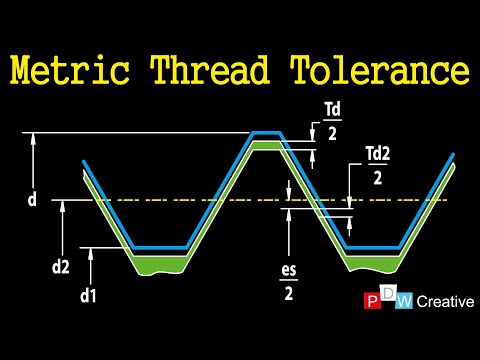

Metric screw thread tolerance

Cutting Imperial Threads On My Metric Mini Lathe (And Metric On Imperial Lathes Too)

PLUMBING THREADS 101 (EVERYTHING YOU NEED TO KNOW) | GOT2LEARN

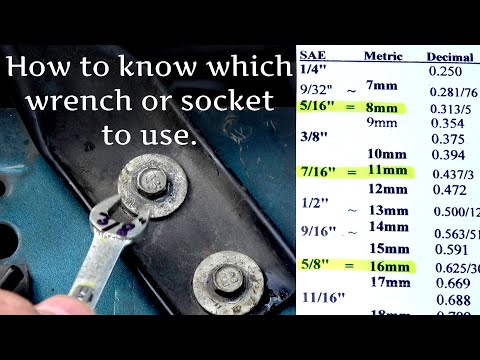

Metric vs Standard, Imperial or SAE - Wrenches, Sockets, Bolt Size Chart + Mechanic Math

Metric Tap Size To Drill Bit Size

Easy Metric Thread Hack

How to identify a metric or imperial bolt quickly!

Shop Tips: Know Your Screw Threads

Bolt grade explained

thread matching #thread

How to Measure and identify Bolts

Metric Fastener Comparisons Episode 13: Comparing DIN 934 hex nuts to ISO 4032 (ISO 8673)

Adaptips: How to identify British and metric threaded fittings

How To - Replicate any thread with Tinkercad!

Internal Imperial Threading on an Import Lathe

Standard vs Metric Wrenches

Комментарии

0:20:51

0:20:51

0:31:58

0:31:58

0:01:16

0:01:16

0:22:40

0:22:40

0:03:24

0:03:24

0:03:39

0:03:39

0:02:46

0:02:46

0:02:23

0:02:23

0:07:38

0:07:38

0:06:22

0:06:22

0:06:15

0:06:15

0:04:27

0:04:27

0:01:04

0:01:04

0:04:36

0:04:36

0:09:37

0:09:37

0:15:21

0:15:21

0:01:32

0:01:32

0:00:21

0:00:21

0:19:06

0:19:06

0:11:52

0:11:52

0:03:20

0:03:20

0:06:39

0:06:39

0:31:52

0:31:52

0:10:17

0:10:17