filmov

tv

Garden Room Workshop Extra | Plinth foundations

Показать описание

In this quick video we take a look at the option of using plinth/concrete pad foundations for timber-frame buildings and compare them to dense concrete block foundations that I used for my garden room build.

Chris Wigley gives some first hand shots of these pads in action with the various metal brackets for different joins. He purchased 2.5 tonne plinths from Easy Pads which support single storey timber buildings up to 20m2. He bought just before lockdown (result of the 2020 pandemic for people of the future!) so had to make the decision to buy or not rather quickly.

There are smaller and bigger ones available. Swift Plinths is another manufacturer worth looking at if you decide these are for you. Enjoy!

Garden Room Workshop Extra | The 15cm rule & Outbuilding heights

Garden Room Workshop Extra | How To Stop Mice Under Your Floor!

Garden Room Workshop Extra | Insulating A Concrete Slab

Garden Room Workshop Extra | Plinth foundations

Garden Room Workshop Extra | How I'd Construct a Cold Roof

Garden Room Workshop: Part 21. Choosing Cladding

Garden room or workshop floor construction process the simple way

Garden Room Workshop: Part 4. Setting out & Foundations

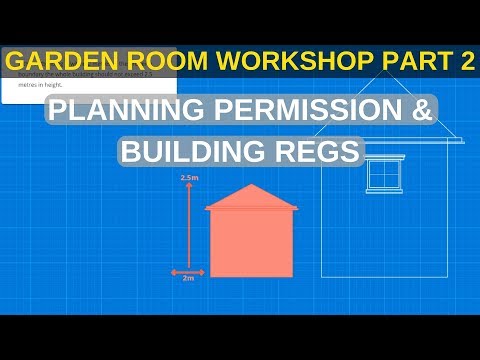

Garden Room Workshop: Part 2. Planning permission & Building regs

IS THIS THE BEST VALUE GARDEN BUILDING IN THE COUNTRY!?

Garden Room Workshop: Part 5. Timber floor

DIY Garden Room - Full Build in Under 15 minutes + Project Cost

Garden Room Workshop: Part 3. Design

Garden Room Workshop: Part 7. Wall framing

How i Built a Garden Room Workshop Flat Roof Quickly - Workshop Build PT4

Garden Room Workshop: Part 6. Insulation & Plywood floor

Building my garden office / workshop - in 7 minutes

Garden Room Workshop: Part 15. Wall Insulation & Vapour Barrier

Garden Room Workshop BUILD Episode 1 || Groundworks and Base Frame

Garden Room Workshop BUILD Episode 2 || Framing the WALLS

Building my garden room / office in 9 minutes (with prices - labour plus materials)

Garden Room Workshop: Part 12. Tyvek, Windows & Doors

Big Build, Garden Room Base

Garden room walls and roof structure

Комментарии

0:07:24

0:07:24

0:03:52

0:03:52

0:05:08

0:05:08

0:04:44

0:04:44

0:08:34

0:08:34

0:03:09

0:03:09

0:12:30

0:12:30

0:11:16

0:11:16

0:07:03

0:07:03

0:08:29

0:08:29

0:19:37

0:19:37

0:14:47

0:14:47

0:06:13

0:06:13

0:14:11

0:14:11

0:13:49

0:13:49

0:11:30

0:11:30

0:07:16

0:07:16

0:16:29

0:16:29

0:14:19

0:14:19

0:18:30

0:18:30

0:08:29

0:08:29

0:19:04

0:19:04

0:08:54

0:08:54

0:19:02

0:19:02