filmov

tv

Testing 6x6 treated posts vs 2x6 laminated posts at DDS engineering part 1

Показать описание

Today we took a trip to DDS engineering to test out some posts that we built. We tested the strength of a laminated post made of three 2x6’s that were glued and nailed together versus a 6x6 treated post. We’ve got to admit, we didn’t accomplish everything we wanted to today. We are going to make some changes to the machine used for testing, and revisit this in a week or two. A huge thank you to Matt and Alex at DDS for making this all happen. Stay tuned for part 2!

Testing 6x6 treated posts vs 2x6 laminated posts at DDS engineering part 1

Wood 6x6 in concrete VS steel anchor (8 years later!) ROTTING! Deck support posts

Some TREATED LUMBER Rots Faster Than Others! WHAT'S THE DIFFERENCE?! (Ground Contact Vs. Non-GC...

How much load can a timber post actually carry?

TORTURE Testing 2x4’s | Standard vs Pressure Treated vs Homemade | Results May Surprise You

Is Quick-Set Concrete Worth It? Testing Quick-Set VS Regular

Fence Post Foam vs Concrete | STRENGTH TEST

How Strong is Lumber? Hydraulic Press Test!

Is it okay to stain or paint pressure treated wood? | Hyde Tools

How To REPAIR SPLITTING 4X4 4x6 6x6 Poles.... Works on All Splitting Lumber & Wood

Pressure Treated Wood - What Grade do you Want for your Project?

6x6?? We DON’T NEED those! 🍀#shorts

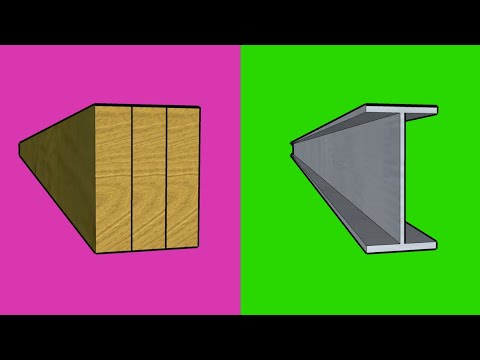

How to compare Timber vs Steel beams

Pressure Treated Lumber vs Cedar Wood

CUTTING 6x6 with 7&1/4 CIRC #carpentry #shorts #fyp

Pressure Treated wood vs non treated wood used on a deck 2/2

How to cut a 6x6 Timber with a miter saw

Dry Packed Fence Post Pull | One Year After Set!

Should you use 3-Ply 2x6 Laminated columns on a Pole Barn?? (32x48)

Post Protector: POST DECAY 101: The Science of Decay, Simplified!

Concrete Post Rot Myth BUSTED - Does Concrete Rot Fence Posts?

Deck Post Cracks❗, should you worry about them❓

20 ft 6x6 posts

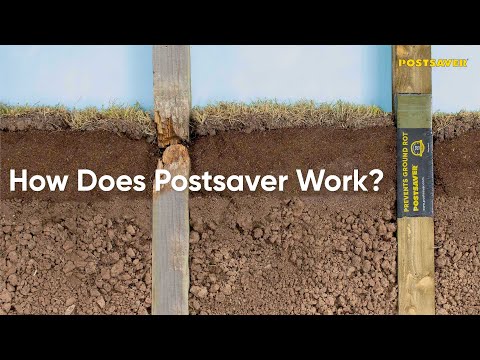

How Does Postsaver Stop Your Fence Posts Rotting?

Комментарии

0:23:41

0:23:41

0:04:54

0:04:54

0:05:11

0:05:11

0:08:57

0:08:57

0:10:09

0:10:09

0:06:11

0:06:11

0:09:36

0:09:36

0:09:03

0:09:03

0:02:49

0:02:49

0:09:26

0:09:26

0:11:19

0:11:19

0:00:16

0:00:16

0:07:08

0:07:08

0:03:00

0:03:00

0:01:00

0:01:00

0:02:11

0:02:11

0:00:48

0:00:48

0:04:08

0:04:08

0:03:28

0:03:28

0:01:10

0:01:10

0:02:25

0:02:25

0:03:32

0:03:32

0:00:37

0:00:37

0:03:45

0:03:45