filmov

tv

Machine your own Low Profile Slitting Saw Arbor

Показать описание

This video shows one of many designs for a low clearance slitting saw arbor you can make yourself, and have forever.

Machine your own Low Profile Slitting Saw Arbor

DIY Low Profile Vice

Making a DIY CNC machine with limited tools

Simple linear slide

Building a homemade full size CNC machine - Linear Bearing Rails - Mini

Low Profile Mill Clamps

Easy Low Profile Side Clamps For The Milling Machine

High efficiency inline duct fan, super suction #inline #ductfan #ventilation #fyp #youtubeshorts

I Fixed My Whirlpool Duet Sport Washing Machine Before It Flooded My Home!

BARBER CUTS OFF LICE!!!! MUST WATCH

Homemade Lathe Machine

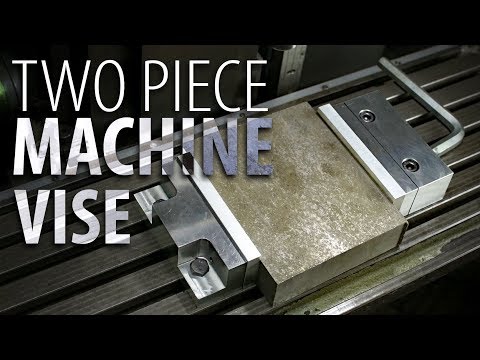

Two Piece Machine Vise Build

if you sleep near your PC... #shorts

Low Profile SFFPC with DIY PC case 1 minute speed build

Put toothpaste in the toilet tank and you'll thank me forever.

Each miner makes HOW MUCH? #bitcoinmining #gpu #bitcoinforbeginners - jp baric tiktok

How To Hand Mount & Balance A Car Tire

the best GPU money can buy (in 2004) #shorts

Tiger Claw - Low Profile Side Clamps for Your CNC Router

adding a CPU cooler to my phone #shorts

My homemade lat pulldown machine🏋️||watch full video 💯 #shortsvideo #fitness #gym #motivational...

Easiest method to remove tire from a rim DIY at home @CarGuruDIY #CarGuruDIY

Mounting and balancing tires 🛞 #mount #balance #tires #fivestarchevrolet #carrolltontx

Nvidia RTX 3080 Mini! The Future of GPUs! #shorts #pcgaming #gpu #aprilfools

Комментарии

0:20:52

0:20:52

0:16:51

0:16:51

0:14:47

0:14:47

0:00:21

0:00:21

0:01:00

0:01:00

0:08:39

0:08:39

0:07:29

0:07:29

0:00:25

0:00:25

0:02:44

0:02:44

0:00:15

0:00:15

0:25:31

0:25:31

0:21:59

0:21:59

0:00:22

0:00:22

0:01:03

0:01:03

0:00:43

0:00:43

0:00:51

0:00:51

0:01:00

0:01:00

0:00:17

0:00:17

0:01:18

0:01:18

0:00:27

0:00:27

0:00:28

0:00:28

0:00:54

0:00:54

0:00:36

0:00:36

0:00:26

0:00:26