filmov

tv

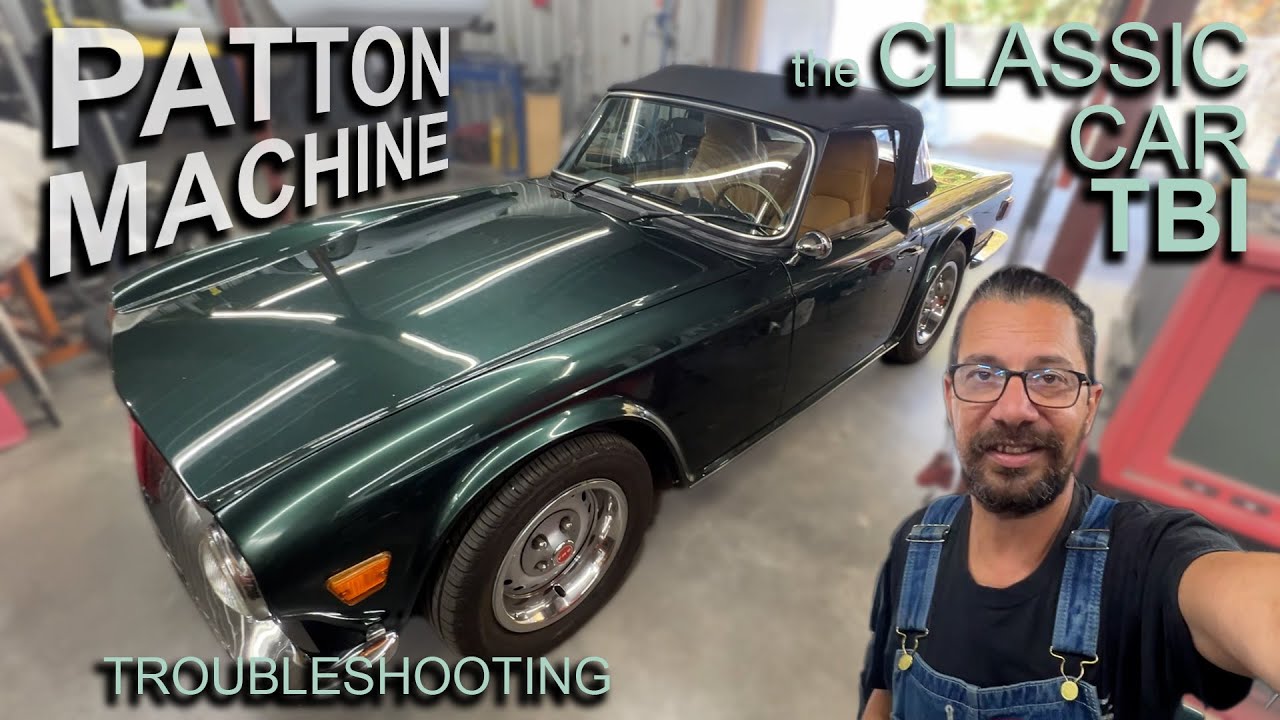

The Patton Machine - Part 1 - Troubleshooting the Throttle Body Injection for classic cars

Показать описание

When the owner of this car asked me if I could help with tuning the Patton Machine I was a little skeptical as I didn't even know what components are there and how they work together. But then I got hooked up and I decided to accept the challenge. So I spent half a day reading and watching videos before I put my hands on the car. And then I couldn't get away from it... Thankfully Rick Patton is patient enough to read through my emails and respond with great advise.

Rusty Beauties Website:

Buy Rusty Beauties merchandise:

Join the Rusty Beauties Facebook group:

If you like this channel please consider supporting it! It takes lots of time and effort to film and edit these videos and your support will help me spare more time for that!

If you wish to support it on Patreon you can do it here:

If you wish to make a one time donation you can use this link to make PayPal donation at any amount:

The financial support to the channel doesn't buy you anything special. There is no such thing as early access or VIP content here as I don't want to take away from those who can't afford it. The financial support is your way of saying "Thank you Elin for taking the time to edit these videos!", but only if you feel like it and you can afford it. Just being here, watching, liking, sharing is also a big support and I appreciate it.

THANK YOU!

#PattonMachine #TBI #tr6

Rusty Beauties Website:

Buy Rusty Beauties merchandise:

Join the Rusty Beauties Facebook group:

If you like this channel please consider supporting it! It takes lots of time and effort to film and edit these videos and your support will help me spare more time for that!

If you wish to support it on Patreon you can do it here:

If you wish to make a one time donation you can use this link to make PayPal donation at any amount:

The financial support to the channel doesn't buy you anything special. There is no such thing as early access or VIP content here as I don't want to take away from those who can't afford it. The financial support is your way of saying "Thank you Elin for taking the time to edit these videos!", but only if you feel like it and you can afford it. Just being here, watching, liking, sharing is also a big support and I appreciate it.

THANK YOU!

#PattonMachine #TBI #tr6

Комментарии

1:10:32

1:10:32

0:39:23

0:39:23

0:28:49

0:28:49

0:10:07

0:10:07

0:00:55

0:00:55

0:00:34

0:00:34

0:00:10

0:00:10

0:00:10

0:00:10

0:00:17

0:00:17

0:00:11

0:00:11

0:00:33

0:00:33

0:00:54

0:00:54

0:00:11

0:00:11

![M48 [Patton] Armored](https://i.ytimg.com/vi/qsmyjDIa4mM/hqdefault.jpg) 0:00:58

0:00:58

0:00:09

0:00:09

0:00:42

0:00:42

0:00:16

0:00:16

0:26:10

0:26:10

0:00:59

0:00:59

0:01:36

0:01:36

0:00:43

0:00:43

0:00:48

0:00:48

0:00:16

0:00:16

0:00:48

0:00:48