filmov

tv

How To Use a Pinion Depth Gauge

Показать описание

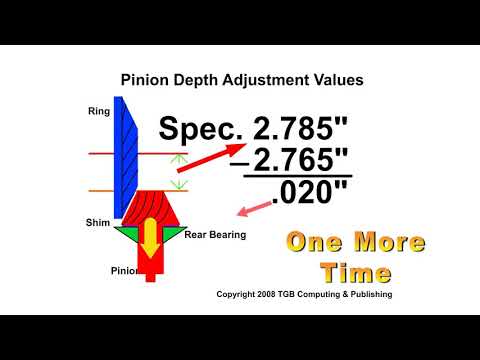

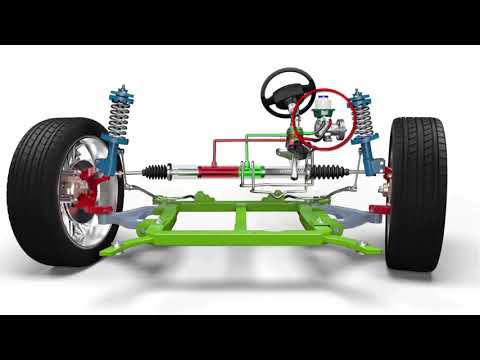

For me, using a pinion depth gauge is the best way to measure pinion depth and finding the perfect pinion shim. It’s way more accurate than going by gear tooth pattern and saves a bunch of time. In this video I show you how to set up and use the tool to measure pinion depth in just about any differential.

I hope you find this information useful!

#ETCGVideo #ETCGDadsTruck

Thanks for watching!

Links

Related Videos

Social Network Links

Stay Dirty

ETCG

Due to factors beyond the control of EricTheCarGuy, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. EricTheCarGuy assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. EricTheCarGuy recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of EricTheCarGuy, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained in this video is the sole responsibility of the user and not EricTheCarGuy®.

I hope you find this information useful!

#ETCGVideo #ETCGDadsTruck

Thanks for watching!

Links

Related Videos

Social Network Links

Stay Dirty

ETCG

Due to factors beyond the control of EricTheCarGuy, it cannot guarantee against unauthorized modifications of this information, or improper use of this information. EricTheCarGuy assumes no liability for property damage or injury incurred as a result of any of the information contained in this video. EricTheCarGuy recommends safe practices when working with power tools, automotive lifts, lifting tools, jack stands, electrical equipment, blunt instruments, chemicals, lubricants, or any other tools or equipment seen or implied in this video. Due to factors beyond the control of EricTheCarGuy, no information contained in this video shall create any express or implied warranty or guarantee of any particular result. Any injury, damage or loss that may result from improper use of these tools, equipment, or the information contained in this video is the sole responsibility of the user and not EricTheCarGuy®.

Комментарии

0:13:31

0:13:31

0:00:35

0:00:35

0:07:17

0:07:17

0:01:30

0:01:30

0:10:20

0:10:20

0:01:30

0:01:30

0:00:36

0:00:36

0:31:23

0:31:23

0:10:01

0:10:01

0:04:48

0:04:48

0:04:16

0:04:16

0:00:45

0:00:45

0:10:51

0:10:51

0:00:50

0:00:50

0:13:31

0:13:31

0:37:45

0:37:45

0:01:06

0:01:06

0:04:10

0:04:10

0:17:50

0:17:50

0:08:34

0:08:34

0:01:09

0:01:09

0:03:37

0:03:37

0:06:06

0:06:06

0:07:20

0:07:20