filmov

tv

How to install grease fittings on riding mower bearings

Показать описание

Most mowers these days do not come with grease fittings on the mower blade bearing mandrels. I show and easy way to add to the life of those bearings by installing a greasezerk fitting on the mandrel.

How to install Grease/Zerk Fittings (Threaded and Drive Type)

drilling and tapping a new grease fitting

How to Change your Grease Fittings

Shop Basics-Installing a Grease Fitting.

Installing Zerk Grease Fitting On Lower Ball Joint Testing And Lubrication Hyundai Santa Fe

How to Mount Grease Fittings on ATV A-arms

How to install grease fittings on riding mower bearings

EASY: Install Grease Nipples the Easy Way!!!

Installing Nylon Fuel Line part number FL-FG0053 on 99-03 Silverado 5.3L

Installing grease fittings in an excavator

does installing grease fitting in a deck spindle housing really work

How to Properly Load a Grease Gun

How Grease Fittings Work

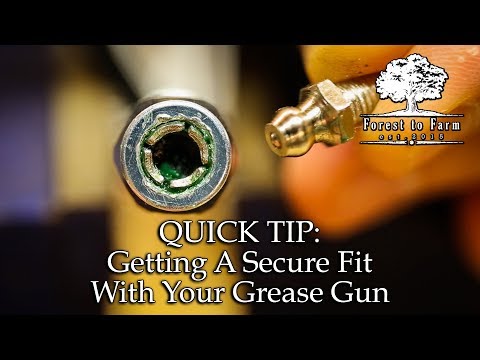

Getting A Secure Fit With Your Grease Gun

Replace Grease Fittings Easily! Simple Steps for Success

Convert Sealed Ball Joint to greaseable Joint

ADD A GREASE ZERK TO ANY JOINT ON YOUR MACHINE

How To Fix a Plugged / Clogged Grease Zerk Fitting Fast!!!

GREASE FITTING FOR HONDA XR150L

Hard to Reach Grease Fittings

Unimog Clogged Grease Fitting Clean Repair

Zerk Grease Fitting Installation

How to fix a broken grease fitting

Change a grease gun cartridge ( easy )

Комментарии

0:02:33

0:02:33

0:05:05

0:05:05

0:06:45

0:06:45

0:12:46

0:12:46

0:32:00

0:32:00

0:02:06

0:02:06

0:05:41

0:05:41

0:01:27

0:01:27

0:18:28

0:18:28

0:13:20

0:13:20

0:02:55

0:02:55

0:02:15

0:02:15

0:01:44

0:01:44

0:03:53

0:03:53

0:02:25

0:02:25

0:09:25

0:09:25

0:09:33

0:09:33

0:02:39

0:02:39

0:06:19

0:06:19

0:11:02

0:11:02

0:00:55

0:00:55

0:02:54

0:02:54

0:04:10

0:04:10

0:02:08

0:02:08