filmov

tv

The Perfect Garage Workbench & Outfeed Table // Part 1

Показать описание

The "Ultimate Workbench" is a dream to have in the shop and after moving into my new shop I have decided to design and build a slightly smaller version better suited for the garage workshop. This Versatile Workbench is an absolute beast. Spanning a respectable 4' x 6' there is plenty of space to utilize as an outfeed table, assembly table, and even a router table!

With all that you've come to expect from an "Ultimate" build this workbench has everything that you could ask for.

- Dust Collection

- Electrical System

- Parts Organizer Bin Storage

- Router Table

- Deep Drawer Storage

I also have a smaller version of this workbench design:

"Shmedium" Workbench [3'x5']

Affiliate Links of products/tools used in the video:

Shop Nation Links:

----------------------------------------------------

Thanks for watching! Be sure to subscribe for future episodes in the series.

#workbenchbuild #workbench #shoporganization

The Perfect Garage Workbench & Outfeed Table // Part 1

Build This Workbench for UNDER $200

Best Garage Workbench 2024 🔥 Top 5 Best Garage Workbench Reviews

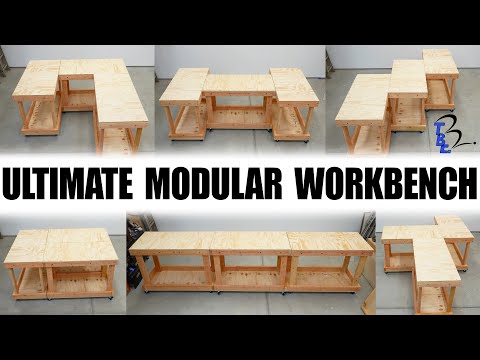

Ultimate Modular Workbench: A Design for Everyone

Building a Garage Workbench for Under $100

Husky Folding Workbench | Garage Storage Ideas

Don't Make a 2x4 Workbench

The PERFECT small shop WORKBENCH

Top: 5 Best Garage Heaters of 2025 || The Best Garage Heaters in 2025 - Reviews

ONE Workbench to do it ALL.

The Perfect Workbench for Small Garages and Tiny Homes!

Smartbench Workbench

Best Workbench for Garage 🔥 Top 5 Best Garage Workbench 2024-2025

The Perfect Hybrid Workbench System: Maximize Your Workshop Space

The PERFECT Workbench for Small Workshops!

10 Best Garage Workbench with Storage and Wheels

Top 7 Best Workbenches 2024

Building a Garage Workbench with Storage Out Of Scrap Wood

How To Build A Workbench - The Best Way

HOW TO BUILD A WORKBENCH FOR GARAGE / DIY Garage Workbench and Shelves

Building a Workbench With Storage in Less Than One Hour - Only One Plywood Sheet and Some 2x4's

The PERFECT Woodworking Workbench // How To Build The Ultimate Hybrid Workholding Bench

ULTIMATE DIY WORKBENCH BUILD

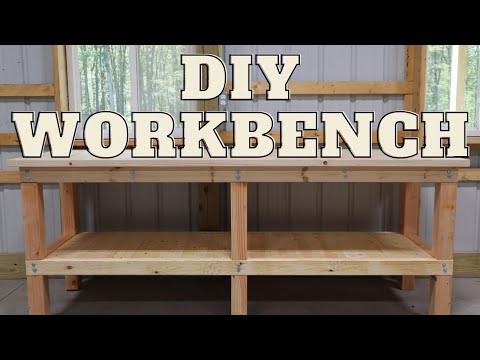

How To Build A Workbench For Your Garage | Easy 2x4 DIY!

Комментарии

0:13:36

0:13:36

0:12:38

0:12:38

0:09:21

0:09:21

0:14:17

0:14:17

0:11:47

0:11:47

0:00:59

0:00:59

0:18:18

0:18:18

0:21:39

0:21:39

0:04:20

0:04:20

0:21:13

0:21:13

0:10:34

0:10:34

0:12:50

0:12:50

0:07:50

0:07:50

0:21:51

0:21:51

0:09:41

0:09:41

0:02:51

0:02:51

0:08:06

0:08:06

0:34:40

0:34:40

0:11:43

0:11:43

0:13:36

0:13:36

0:05:32

0:05:32

0:13:10

0:13:10

0:14:18

0:14:18

0:10:45

0:10:45