filmov

tv

How To Align Track Over Baseboard Joints - Model Railway Tutorial

Показать описание

How to align track over a baseboard joint on your model railway - Tutorial

If you've ever needed to know how to align tracks across baseboard joints then this is the tutorial for you. If (like me) you're building a portable or exhibition style layout that needs to come apart then making sure trains run smoothly across the joints between baseboard is absolutely crucial. It can also be useful for permanent layouts too though where the railway crosses in front of a doorway and you want a section that hinges up to allow access.

In this tutorial I'll show you the technique I use to ensure tracks maintain their alignment no matter how many times you dismantle and assemble the layout. I'll also cover how to connect the two sections electrically too as well as sharing some tips on how to blend the scenery together to make the baseboard joints almost invisible!

Products Used:

Chapters:

00:00 - Intro

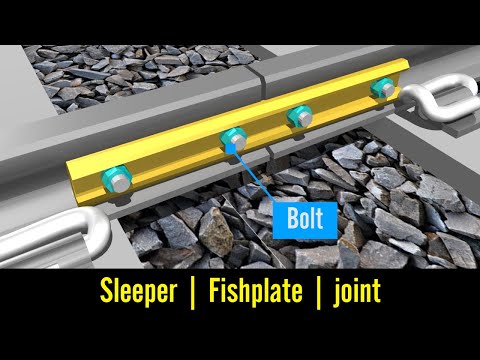

01:43 - Removing Sleepers

03:10 - Brass Screws

05:10 - Soldering The Rails

07:18 - Cutting The Rails

08:28 - Power Across Baseboards

11:27 - Ballasting Technique 1

13:51 - Ballasting Technique 2

15:07 - The Reveal & Testing

Thanks for watching! 😃

If you've ever needed to know how to align tracks across baseboard joints then this is the tutorial for you. If (like me) you're building a portable or exhibition style layout that needs to come apart then making sure trains run smoothly across the joints between baseboard is absolutely crucial. It can also be useful for permanent layouts too though where the railway crosses in front of a doorway and you want a section that hinges up to allow access.

In this tutorial I'll show you the technique I use to ensure tracks maintain their alignment no matter how many times you dismantle and assemble the layout. I'll also cover how to connect the two sections electrically too as well as sharing some tips on how to blend the scenery together to make the baseboard joints almost invisible!

Products Used:

Chapters:

00:00 - Intro

01:43 - Removing Sleepers

03:10 - Brass Screws

05:10 - Soldering The Rails

07:18 - Cutting The Rails

08:28 - Power Across Baseboards

11:27 - Ballasting Technique 1

13:51 - Ballasting Technique 2

15:07 - The Reveal & Testing

Thanks for watching! 😃

Комментарии

0:17:30

0:17:30

0:02:38

0:02:38

0:03:48

0:03:48

0:02:33

0:02:33

0:08:47

0:08:47

0:03:31

0:03:31

0:03:19

0:03:19

0:05:34

0:05:34

![[Paper Club] Who](https://i.ytimg.com/vi/4o_ic83U1Kw/hqdefault.jpg) 1:00:55

1:00:55

0:33:13

0:33:13

0:01:19

0:01:19

0:15:13

0:15:13

0:13:33

0:13:33

0:06:40

0:06:40

0:04:13

0:04:13

0:05:03

0:05:03

0:03:35

0:03:35

0:02:56

0:02:56

0:10:58

0:10:58

0:01:02

0:01:02

0:03:00

0:03:00

0:01:24

0:01:24

0:07:52

0:07:52

0:06:43

0:06:43