filmov

tv

Rack and Pinion Design 1 - spur gear design in solidworks

Показать описание

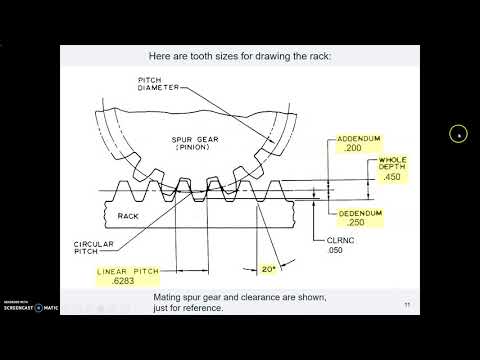

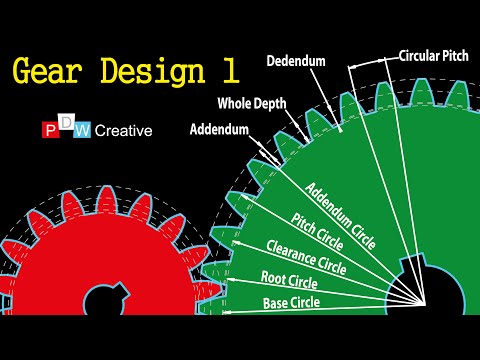

How to design a working steering rack, rack and gear or rack and pinion mechanism, understand how the pitch circle drives other factors. Identify which characteristics control the gear design and why the module, number of gear teeth and pressure angle are important. The relationship between addendum, base diameter, pitch diameter, clearance diameter and root diameter is also discussed.

This video gives a practical demonstration on how to detail the spur gear, involute curve, gear tooth profile, pitch circle, circular pitch, dedendum, addendum, whole depth, addendum circle, clearance circle, root circle, base circle, pressure angle and how it relates to rack design.

This video gives a practical demonstration on how to detail the spur gear, involute curve, gear tooth profile, pitch circle, circular pitch, dedendum, addendum, whole depth, addendum circle, clearance circle, root circle, base circle, pressure angle and how it relates to rack design.

Rack and Pinion Design 1 - spur gear design in solidworks

Basic Mechanisms: Rack and Pinion

Rack & Pinion Gears

Rack And Pinion Design With Solid Edge

How to Design a Rack and Pinion Assembly in Fusion 360 - Part 1

Rack and Pinion Design - involute spur gear and rack with motion in solidworks

ME05 rack & pinion gears

Rack and Pinion Design 2 - Rack gear design in Solidworks

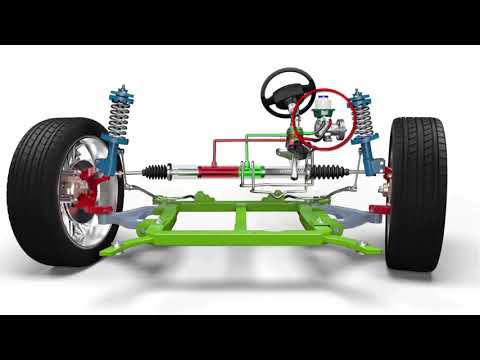

Rack And Pinion Steering System

A simple rack and pinion gear assembly

Spur Gear Design 1 - How gears work

HOW TO DESIGN RACK AND PINION||SOLID WORKS||TUTORIAL#1 [RAP]

rack and pinion mechanism 1

Rack and Pinion Mechanism

Reciprocating Mechanism | Rack & Pinion | 3d cad design & Animation

How To Center a Steering Rack

Helical Rack and Pinion #engineering #solidworks

Rack and pinion Arrangement of gears

RACK AND PINION DESIGN SOLIDWORKS 2020

Two Different Gearbox Design📌 1) Bevel Gearbox 2) Differential Gearbox #mechanicaldesign #3dcad #3d...

Design Rack and pinion gear drive | Autodesk Inventor

' RACK & PINION MECHANISM ' in creo #3dmodelling #creomechanism #rack&pinion #sup...

EASY130 Rack and pinion fixture

Rack and pinion Mechanism for Automatic Boating #mechanical #mechanism #solidworks #3ddesign #cad

Комментарии

0:24:17

0:24:17

0:00:35

0:00:35

0:00:16

0:00:16

0:04:29

0:04:29

0:11:00

0:11:00

0:42:33

0:42:33

0:14:39

0:14:39

0:18:19

0:18:19

0:00:50

0:00:50

0:00:11

0:00:11

0:05:52

0:05:52

0:07:17

0:07:17

0:00:36

0:00:36

0:00:36

0:00:36

0:00:06

0:00:06

0:00:59

0:00:59

0:00:14

0:00:14

0:00:16

0:00:16

0:07:09

0:07:09

0:00:09

0:00:09

0:25:16

0:25:16

0:00:20

0:00:20

0:00:52

0:00:52

0:00:07

0:00:07