filmov

tv

Building a submarine and diving to MAX DEPTH (PT1)

Показать описание

If you feel like this video has improved your life, share it with:

- Your dad, mom, brother, uncle and your entire family (if you have one)

- Your life partner (boyfriend / husband / girlfriend / wife)

- Your 10 best friends

- Your drink buddies

- Your university / high school teacher

- Your coworker / coworkers

- Your boss

- All of your employees (if you own a business)

- Your university / high school colleges who you don’t consider friends

- Your hairdresser

- Your therapist

- Your doctor / dentist

- A random person on the street (you can use this video as a pickup line)

- Your dog / cat / rat / fish (this will get us some extra views)

- JJJreact

0:00 - Upgrades necessary

1:32 - Tether

7:00 - Endcaps

12:20 - Roadtrip

13:49 - THE MINE

15:40 - In the mineshaft

22:48 - Results

____________

Music:

License ID: XQZV1W9O5gO

♪ Sunset (Prod. by Lukrembo)

Building a submarine and diving to MAX DEPTH (PT1)

Diving My Homemade Submarine for the First Time Publicly!

My DIY Submarine Dives As Deep As Possible (PT2)

$2.5MIL💰Private SUBMARINE | 3 people & 300 meters deep #shorts

We Built A Homemade Survival SUBMARINE

Building a DIY submarine

Surviving The Ocean In A Homemade Submarine

Homemade Submarine Dive Trial - Throwback!

Building the MOST MANEUVERABLE submarine

Building a Lego-powered Submarine 4.0 - automatic depth control

I Built a REAL Submarine and Dove it with My GF inside!

Homemade SUBMARINE VS. SUBMARINE Underwater Challenge!! (THEY ACTUALLY WORK!!)

Diving Homemade Submarine At Whiteswan Lake

24 HOUR BOX FORT SUBMARINE CHALLENGE!! 📦💦 Scuba Tanks, Onboard Oxygen & More!

SUBMARINE VS MINI SUBMARINE UNDERWATER CHALLENGE!!! (Gone Wrong..)

Vented Ballast Tank for a RC Submarine - principle.

I Tested a Submarine in my Fish Tank 🐠

Inside Secret Shipyards Building US Massive Billions $ Nuclear Submarine

Titanic Submarine Implosion Simulation | OceanGate Titan Implosion Example

Cheap PVC submarine DIY

We 3D printed a submarine (dives down to 85 meters / 280 feet)

I Built a LEGO Submarine!

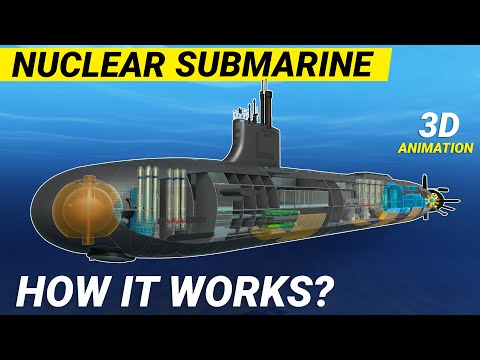

Submarine Nuclear Power | Engineering behind it Nuclear Reactor How it Works

How I Built A Homemade Submarine

Комментарии

0:23:52

0:23:52

0:08:09

0:08:09

0:19:23

0:19:23

0:00:15

0:00:15

0:14:03

0:14:03

0:27:33

0:27:33

0:15:04

0:15:04

0:02:01

0:02:01

0:17:52

0:17:52

0:07:27

0:07:27

0:08:20

0:08:20

0:21:37

0:21:37

0:29:43

0:29:43

0:19:07

0:19:07

0:34:33

0:34:33

0:08:54

0:08:54

0:00:24

0:00:24

0:15:35

0:15:35

0:00:16

0:00:16

0:13:19

0:13:19

0:17:05

0:17:05

0:14:47

0:14:47

0:14:07

0:14:07

0:14:09

0:14:09