filmov

tv

Can't Wait.. Changing My Own Spindle

Показать описание

Can't Wait.. Changing My Own Spindle

[ENG SUB]✨ Love at First Sight, He Asked My Age and Pushed for Marriage #DRAMA #PureLove

Cô Gái Bỏ Nhà Đi 3 Năm Trở Về Bị Gia Đình Khinh Bỉ Ra Mặt, Ai Ngờ Cô Là Vợ Tổng Tài Nghìn Tỷ...

Milky Chance - Stolen Dance (Official Video) [HD Version]

this will download everything faster on your switch

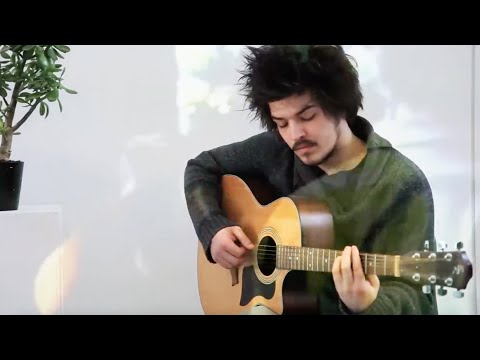

He’s been putting in work 👏

Why hasn't Apple invented this yet?!

[ENG SUB]✨Trading My Afterlife to Relove the Man I Let Die #DRAMA #PureLove

A CAPRICORN?! #Shorts

You got it, dude #shorts

What Hyperrealistic Cake Should I Make Next?!

Air Supply - Making Love Out Of Nothing At All ( Video Lyrics )

How to Get On Your Teacher’s Good Side

Stop Throwing Away Orange Peel! Make the Fondest Snack (Only 2 Ingredients)

THIS FRUIT IS GLITCHED in Grow A Garden ! #roblox #robloxshorts #robloxgames

Children's encouragement song - I do it - motivational baby song | Hooray kids songs & nurs...

I Will Guess Your Name In One Minute!

Best Advice to Small Business Owners

Rumors (Music Video)

[ENG SUB]✨Five Million from Boyfriend's Mother to End Our Relationship #DRAMA #PureLove

Minecraft, But I Can't Use The Letter O

Fleetwood Mac - The Chain (Official Music Video) [HD]

“Hey Boy” Karaoke Sing Along Song | Over the Moon | Netflix Family

Tevin Campbell - Can We Talk (Official Video)

Комментарии

0:00:50

0:00:50

![[ENG SUB]✨ Love](https://i.ytimg.com/vi/0tAyLzYk8hk/hqdefault.jpg) 3:16:40

3:16:40

2:27:39

2:27:39

0:05:14

0:05:14

0:00:20

0:00:20

0:00:59

0:00:59

0:01:00

0:01:00

![[ENG SUB]✨Trading My](https://i.ytimg.com/vi/MNmur4Im8-k/hqdefault.jpg) 2:32:22

2:32:22

0:00:17

0:00:17

0:00:15

0:00:15

0:00:20

0:00:20

0:05:41

0:05:41

0:00:26

0:00:26

0:00:57

0:00:57

0:00:24

0:00:24

0:01:57

0:01:57

0:02:47

0:02:47

0:03:26

0:03:26

0:03:22

0:03:22

![[ENG SUB]✨Five Million](https://i.ytimg.com/vi/ZQKpNv7vw-0/hqdefault.jpg) 1:29:54

1:29:54

0:01:00

0:01:00

0:04:55

0:04:55

0:01:46

0:01:46

0:04:17

0:04:17