filmov

tv

How to Drill Straight Holes

Показать описание

Sometimes it really important that holes are drilled straight (or perpendicular) to the work piece. In this video I show 3 different home made jigs that will help you achieve that and a little idea that means you will never need a jig again!

Amazon links to the equipment used in this video...

UK Links:

US Links:

The Amazon links above are affiliate links. It doesn't cost you anything to click on them but I do earn a small commission if you do. As an Amazon Associate I earn from qualifying purchases.

Amazon links to the equipment used in this video...

UK Links:

US Links:

The Amazon links above are affiliate links. It doesn't cost you anything to click on them but I do earn a small commission if you do. As an Amazon Associate I earn from qualifying purchases.

#1 Easiest Trick to DRILL STRAIGHT! (Drill at Perfect 90 Degrees...Fastest Method!)

🟢 Drill STRAIGHT Holes (5 Easy Ways without a Drill Press)

How to Drill Straight Holes

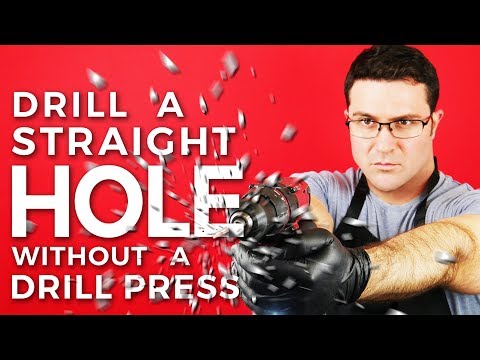

Drill a Straight Hole without a Drillpress

Straight Holes Every Time!

This woodworking tip will demonstrate drilling right down the center

How to Drill Straight Holes with a Portable Drill | April Wilkerson

How To Drill Straight Holes Without A Drill Press

DI Drill-powered Tongue Jack Adapter Under $20

How To Drill A Straight Hole Without A Drill Press

How To Drill Straight Holes with a Hand Drill

How to Drill A Straight Hole | Home Hack

Drill Straight Holes Every Time!

Make a Anywhere Right-Angle Drill Guide | Tricks of the Trade

How to drill straight holes without a drill press. No block needed

Drilling straight holes without a drill press - Making a Drill Guide Jig

Levoite™ 30 45 90 Angled Drill Guide Jig for for Angled and Straight Hole

Drill Guide I Drilling Straight Holes I 4K

11 DRILLING TIPS AND TRICKS (And Mistakes To Avoid!)

How to drill a perfectly straight hole every single time using this quick trick! (Tool Tip Tuesday)

8 AMAZING Cordless Drill TIPS!

How to Drill Straight without a Drill Press / How to Drill Straight Holes

#shorts Metal Dowel Jig for Drill Guide for Straight Holes,Including Drill Bit Set 1/4', 5/16&...

How to DRILL A HOLE in the CENTER of a dowel!

Комментарии

0:03:10

0:03:10

0:03:58

0:03:58

0:13:12

0:13:12

0:01:00

0:01:00

0:02:05

0:02:05

0:05:39

0:05:39

0:00:57

0:00:57

0:01:01

0:01:01

0:05:12

0:05:12

0:04:53

0:04:53

0:00:58

0:00:58

0:00:23

0:00:23

0:06:02

0:06:02

0:04:45

0:04:45

0:05:19

0:05:19

0:03:33

0:03:33

0:00:35

0:00:35

0:09:30

0:09:30

0:08:19

0:08:19

0:02:39

0:02:39

0:09:17

0:09:17

0:01:55

0:01:55

0:00:47

0:00:47

0:00:34

0:00:34