filmov

tv

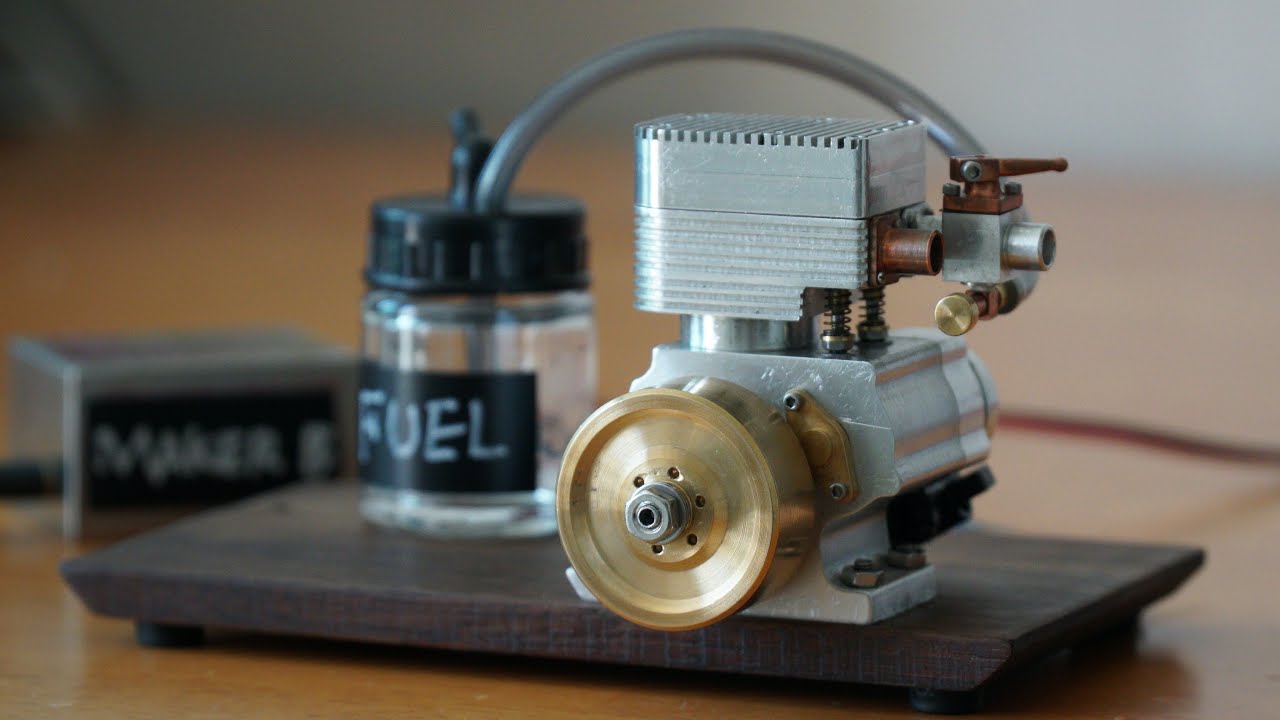

Making a 2.4cc Petrol (Gasoline) Engine

Показать описание

Thank you for watching :)

I hope you enjoy this as much as I do!

Making a 2.4cc Petrol (Gasoline) Engine

2.2cc Mini Single-cylinder Four-stroke Evaporative Water-cooling Gasoline Internal Combustion Engine

fridge compressor two stroke engine

DIY 220V Generator with 2 Cylinder Engine #Shorts

Self Unboxing Steampunk Engine - Mini 4-Stroke Engine

Which is the best Stirling engine

internal combustion in syringe 💉 😱|| you can make it petrol engine ||

2 Stroke Gasoline Mini Engine Only 2500 😱 | Best mileage setting petrol Engine | Small Engine |

Building a HIGH Revving 4 Cylinder Mini Engine - 4 Stroke Engine Build

I completely converted the regular engine to 4 cylinders from scrap

Incredible Homemade Doomsday Style Gyrocopter #shorts #aviation #aircraft #amazing #helicopter #fly

Motorize Your Bicycle | Remake Project

Motorize Your Bicycle / Build a Motorized Bike Using grass cutting machine / Homemade TRIMMER BIKE

GIANT RC GAS TRUCK IS THE SIZE OF MINI DIRT BIKE 😳

100cc mini pocket rocket

kids bike assembly in 1 min

Stihl ms 881 vs Huge tree.

4-Year-Old Motocross Kid Wins 3rd in Dirt Bike Race #shorts #dirtbike

How does petrol engine work? (By Mr Animation) #Shorts

Segway ninebot go kart pro electric drift skid shakedown first drive test fun

Homemade Electricity Generator | AC DC Generator

Precision of Iridium vs copper spark plugs #shorts

How To Replace Fuel Line on 2-Stroke/2-Cycle Engines (Weed Eater, Chainsaw, Hedge Trimmer, Blower)

Rc Boat System Self-Righting #Shorts

Комментарии

0:15:24

0:15:24

0:00:26

0:00:26

0:00:19

0:00:19

0:00:22

0:00:22

0:04:40

0:04:40

0:00:33

0:00:33

0:01:21

0:01:21

0:10:04

0:10:04

0:11:08

0:11:08

0:29:41

0:29:41

0:00:16

0:00:16

0:10:34

0:10:34

0:05:31

0:05:31

0:00:25

0:00:25

0:00:12

0:00:12

0:00:16

0:00:16

0:01:00

0:01:00

0:00:15

0:00:15

0:01:00

0:01:00

0:00:18

0:00:18

0:08:09

0:08:09

0:00:32

0:00:32

0:04:44

0:04:44

0:00:23

0:00:23