filmov

tv

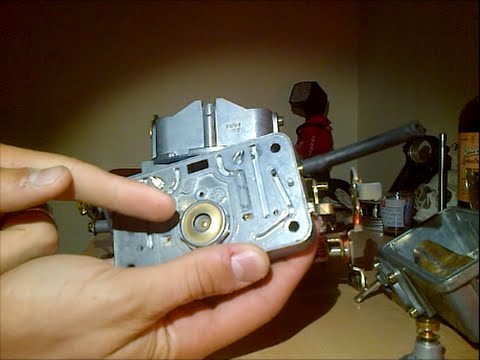

HOLLEY POWER VALVE TUNING- Everything You Need To Tune Your Power Valve | Holley Carb Secrets |

Показать описание

Holley Power Valve and How to tune power valve along with so much more info. I've got my carb ls dialed in and I thought I'd show you how to set up one of the most viable items on your carb. On my carbureted ls I installed a vacuum gauge and an AFR gauge and went to town. Theres very little info when it comes to a holley carb and much less when you get into the PVCR, IAB, IFR etc. Tuning a holley carb is easy, once you know how all the systems operate. Hopefully this helps someone in the future looking to modify their holley 600 650 750 vacuum secondary or double pumper. Trying to catch up to the driveway engineer so lend me your power!

HOLLEY POWER VALVE TUNING- Everything You Need To Tune Your Power Valve | Holley Carb Secrets |

Power Valves Explained: How they work, how to tune

Holley Carb Power Valve Tuning - Summit Racing Quick Flicks

Holley CARB TUNING episode 1. UNDERSTANDING & TUNING THE POWER VALVE CIRCUIT.

Holley Power Valve Overview

Holley Power Valve - Tech Tip Minute

Set & Tune Holley Carburetor Jets & Power Valves

Holley Carb Tuning Tips! | Engine Masters | MotorTrend

Holley Carburetor: Power Valve Explained

Holley Carb Power Valves - Most Overlooked Carb Performance Aspect

Holley Power Valve Test

The Ultimate Holley 4150 Tuning Video! ( As easy as 1 2 3 sort of )

HOW TO: HOLLEY CARB TUNING TRICKS (408 STROKER SBF)

Holley Power Valve Replacement with the Carburetor Still on the Car

Holley 4150 tuning like a Boss: Tune for power, economy, and drivability #400sbc #carburetor

HOW TO: Testing a Power Valve

Everything You Need To Know About Edelbrock Carbs In A Minute

The Holley Carb Adjustment That Has A Twist - A Seemingly Simple Variation With A Big Difference

Holley Set-Up and Adjust Step By Step

Holley 4150 carburetor tuning “secret” you probably don’t know about.

Needle & Seat adjustments, float level, and blown power valves. Holley Carburetor Tuning Ep2

Holley Carb Tuning Secrets Revealed!- Part 1 | How to Tune A Holley Carburetor Tips And Tricks |

Quick Fuel Technology Power Valve Tech

MOST COMMON Misadjusted Holley Carburetor Setting (2 second Fix)

Комментарии

0:07:24

0:07:24

0:21:16

0:21:16

0:16:27

0:16:27

0:19:34

0:19:34

0:08:17

0:08:17

0:01:16

0:01:16

0:09:11

0:09:11

0:03:24

0:03:24

0:09:00

0:09:00

0:09:44

0:09:44

0:01:31

0:01:31

0:45:23

0:45:23

0:18:18

0:18:18

0:05:29

0:05:29

0:25:45

0:25:45

0:15:22

0:15:22

0:01:03

0:01:03

0:08:16

0:08:16

0:11:54

0:11:54

0:13:39

0:13:39

0:29:04

0:29:04

0:09:15

0:09:15

0:03:30

0:03:30

0:07:52

0:07:52