filmov

tv

Adding Zerk / grease fittings to swing arm pivot, by SystemTechRacing

Показать описание

Less friction means smooth plush suspension. Adding grease fittings to swing arm pivot. I gotta tell ya, pumped in grease to the assembly seems to do a better job than just packing the bearings. A one minute job to lube this pivot now.

How to install Grease/Zerk Fittings (Threaded and Drive Type)

The Best Grease Gun Adapter! ! How to grease joints with no grease fittings

How to Fix Clogged Grease Zerk Fitting! Plus New Grease Gun!

ADD A GREASE ZERK TO ANY JOINT ON YOUR MACHINE

How to Mount Grease Fittings on ATV A-arms

Zerk Grease Fitting Installation

drilling and tapping a new grease fitting

How to Change your Grease Fittings

How Grease Fittings Work

Adding Zerk / grease fittings to swing arm pivot, by SystemTechRacing

Convert Sealed Ball Joint to greaseable Joint

How to Grease Zerk Fittings: ATV Edition | Partzilla.com

How to grease control arms no grease zerk fitting @MaXpeedingRods

Installing Zerk Grease Fitting On Lower Ball Joint Testing And Lubrication Hyundai Santa Fe

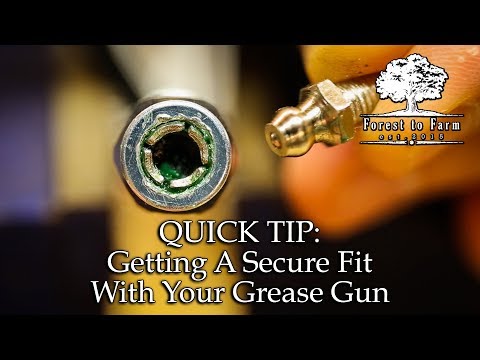

Getting A Secure Fit With Your Grease Gun

how to grease a ball joint without a zerk fitting

Grease Zerk fitting won't accept grease

Hard to Reach Grease Fittings

How to do a Chassis Lube (Ball Joints, Tie Rods Ends, and more!) | AnthonyJ350

No grease fittings? No problem!! | Ford F250 | asmr grease

How To Fix a Plugged / Clogged Grease Zerk Fitting Fast!!!

Grease Any Joint, Tie Rod, Links, Ball Joint Without Zerk Fitting | Super Easy

How to install grease fittings on riding mower bearings

Installing grease fittings in an excavator

Комментарии

0:02:33

0:02:33

0:05:54

0:05:54

0:16:41

0:16:41

0:09:33

0:09:33

0:02:06

0:02:06

0:02:54

0:02:54

0:05:05

0:05:05

0:06:45

0:06:45

0:01:44

0:01:44

0:06:07

0:06:07

0:09:25

0:09:25

0:01:46

0:01:46

0:02:06

0:02:06

0:32:00

0:32:00

0:03:53

0:03:53

0:01:56

0:01:56

0:01:26

0:01:26

0:11:02

0:11:02

0:04:42

0:04:42

0:02:24

0:02:24

0:02:39

0:02:39

0:09:08

0:09:08

0:05:41

0:05:41

0:13:20

0:13:20