filmov

tv

Tear Down and Wiring Upgrade + Complete disassembly, cleaning, and reassembly of mini lathe

Показать описание

This video is a complete tear down, clean, discovery, grease, and rebuild of the MINI LATHE. (MUCH) More information below!

Please like and subscribe if this was helpful!

Stuff from this video:

Stuff on the lathe:

Lathe tools:

Other stuff:

Music:

Please like and subscribe if this was helpful!

Stuff from this video:

Stuff on the lathe:

Lathe tools:

Other stuff:

Music:

Tear Down and Wiring Upgrade + Complete disassembly, cleaning, and reassembly of mini lathe

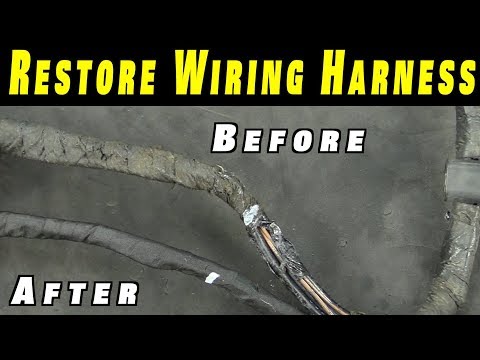

How To Restore Any Wiring Harness

Be Careful Of 'Updated' Wiring

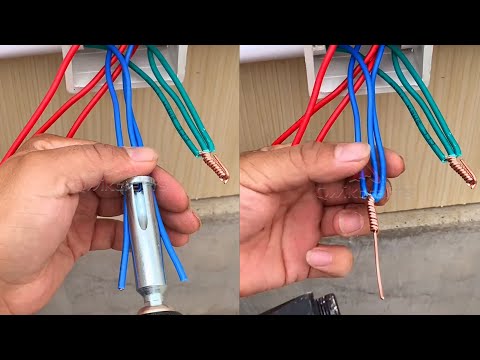

Do you know the correct method of stranded wire?

Re-Wire Your Whole Damn Car - How To Do It Correctly & Inexpensively

How to Easily Strip Wire 2021

Soldering tips and tricks - Tip5 Don't try to solder a wire when flux from solder was evapora...

2023 Lexus RZ 450e “steer by wire”

Engine Reinstall & ECU Upgrade! Complete Wiring Harness Build for the Volvo 242 5 Cyl Turbo Swap

Beginner guide to ECU install and wiring + editable wiring diagram download

Simplest Electric Bike Wiring Diagram

Fiber splicing//What happens if copper wire are put into a fusion splicer

WATCH Me Re-Wire An ENTIRE BOAT!!!

BIG 3 Upgrade with 2 Gauge Welding Wire + TESTING!

M4 Mac mini FULL Teardown - Apple Finally FIXED IT?!

Two wire flasher module teardown with unexpected find

How To Abandon Knob & Tube Wiring in a Wall or Ceiling

DIY Welding Upgrade: A Game-Changer for Our Workshop! | Shop Made Tools

Mixer grinder wiring connection | Mixer grinder | Mixer grinder connection | Mixer grinder wiring

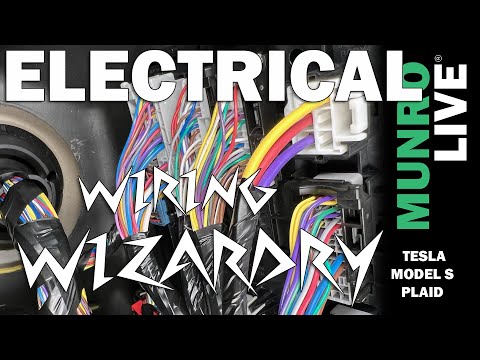

Plaid Low Voltage Wiring First Look | Tesla Plaid Teardown

Motorcycle indicator wiring diagram/bike turnsignal wiring

Single Phase Electricity Explained - wiring diagram energy meter

Master switch wiring with two way switch (DPDT) demonstration #shorts #diy #wiring #trending

The Better Way To Wire Outlets #shorts

Комментарии

0:27:27

0:27:27

0:08:50

0:08:50

0:00:58

0:00:58

0:00:39

0:00:39

0:19:10

0:19:10

0:00:10

0:00:10

0:00:47

0:00:47

0:00:26

0:00:26

0:28:07

0:28:07

0:16:31

0:16:31

0:01:15

0:01:15

0:00:57

0:00:57

0:11:19

0:11:19

0:16:51

0:16:51

0:12:18

0:12:18

0:10:12

0:10:12

0:13:35

0:13:35

0:45:19

0:45:19

0:00:15

0:00:15

0:30:38

0:30:38

0:00:25

0:00:25

0:10:10

0:10:10

0:00:13

0:00:13

0:00:40

0:00:40