filmov

tv

DIY Testing, Fixing, & Recharging A/C

Показать описание

No AC? Leak test. Component test & replacement. Evacuate and recharge! This is my first go at this too! Allegedly this refrigerant does not deplete Ozone.

"Who told you?!" Servicing AC is a regulated industry in most parts. I am not certified, and have precious little AC experience. Yes, legit, a Provincially-Certified AC Technician told me not to publish this video, citing that he didn't want to see me get in trouble because of regulations. I gambled and did it anyway. Point out this paragraph in your comment below, and get an "A"!

"Rookie Mistake!?" Some of you are telling me I shouldn't invert the can for recharging. Every can I have used says to invert the can for recharging. I'm going to trust the can.

"Pro Tip!!" Before yanking the $$$ component, confirm that the electrical to is actually has both positive AND negative going to it - no sense condemning a component when it's actually source or ground to blame.

"It's Gone!!" Kid2 learned to drive in this, and now he's sold it; it's gone. Freedom!

Vevor Vacuum Pump:

Orion A/C Gauge Set:

Emzone A/C Recharge Kit:

Pick-N-Pull:

BC Regulations:

"Who told you?!" Servicing AC is a regulated industry in most parts. I am not certified, and have precious little AC experience. Yes, legit, a Provincially-Certified AC Technician told me not to publish this video, citing that he didn't want to see me get in trouble because of regulations. I gambled and did it anyway. Point out this paragraph in your comment below, and get an "A"!

"Rookie Mistake!?" Some of you are telling me I shouldn't invert the can for recharging. Every can I have used says to invert the can for recharging. I'm going to trust the can.

"Pro Tip!!" Before yanking the $$$ component, confirm that the electrical to is actually has both positive AND negative going to it - no sense condemning a component when it's actually source or ground to blame.

"It's Gone!!" Kid2 learned to drive in this, and now he's sold it; it's gone. Freedom!

Vevor Vacuum Pump:

Orion A/C Gauge Set:

Emzone A/C Recharge Kit:

Pick-N-Pull:

BC Regulations:

How to Recharge Your Car's AC System (Fast and Easy)

Why You Should Not Recharge Your Truck or Car's A/C Yourself

How to Properly Recharge Your AC System

Properly Recharge Your Car's Air Conditioning AC System in LESS than 5 Minutes! -Jonny DIY

How to Repair and Recharge A Portable Air Conditioner

I can't believe Mechanics don't know How to Recharge AC system correctly!

A/C Leak Testing, Repair, Evac and Recharge (ANY CAR!)

How to test and fix Android smartphone charging system using Multimeter and current meter

DIY flashlight charging repair

How to Vacuum Down and Recharge Your A/C System! - EASY

How to Recharge a Car's A/C System Using a Manifold Gauge Set & Vacuum Pump - Air Condition...

RYOBI 18V Battery Not Working? [Easy DIY Charging Hack]

A/C Not Recharging - Refrigerant Not Coming Out Fix

Dead 12V Car Battery Recovery Recharge & Revive From 5V

How to revive DEWALT Lithium battery? Not charging, If jumpstart won't work, try manual reset...

10 Min. ReCharge MrCool DIY

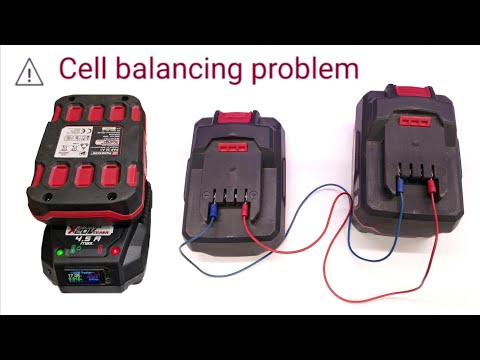

Not Charging Parkside Battery! Charger leds is blinking and Cell balancing problem. How I Fix it?

Air Conditioning Recharge DIY Blows 42 degree's Honda Civic AC system Civic

Best battery charging hack for dead batteries!!!!

How to fix 12-volt charging port in your car.

How to Diagnose and Recharge Your AC System with Refrigerant - Using an A/C Manifold Gauge Set

Cheap Charging Wires Are Destroying Your iPhone...

36v E bike Battery NOT Charging - Repair - Li Ion 18650 Dead cells - DIY

FIX Hoverboard BATTERY charging PROBLEM

Комментарии

0:07:59

0:07:59

0:04:25

0:04:25

0:13:09

0:13:09

0:03:37

0:03:37

0:46:41

0:46:41

0:07:46

0:07:46

1:16:14

1:16:14

0:11:07

0:11:07

0:12:56

0:12:56

0:19:14

0:19:14

0:15:57

0:15:57

0:08:09

0:08:09

0:01:23

0:01:23

0:06:38

0:06:38

0:08:13

0:08:13

0:08:05

0:08:05

0:08:11

0:08:11

0:08:28

0:08:28

0:00:14

0:00:14

0:03:15

0:03:15

0:11:51

0:11:51

0:02:44

0:02:44

0:08:48

0:08:48

0:02:41

0:02:41