filmov

tv

How to make nylon fuel lines the RIGHT way without the tool!

Показать описание

Here’s the RIGHT way to make or repair nylon fuel lines without having the special nylon fuel line making tool! They can be a pain and are a critical part of your fuel system, but if done correctly can save you money and time! As always be safe and this is just a how-to by me, I do not claim to be a professional and do not assume any liability of what you do! I appreciate you watching, go ahead and like,subscribe and comment if this helped you out!

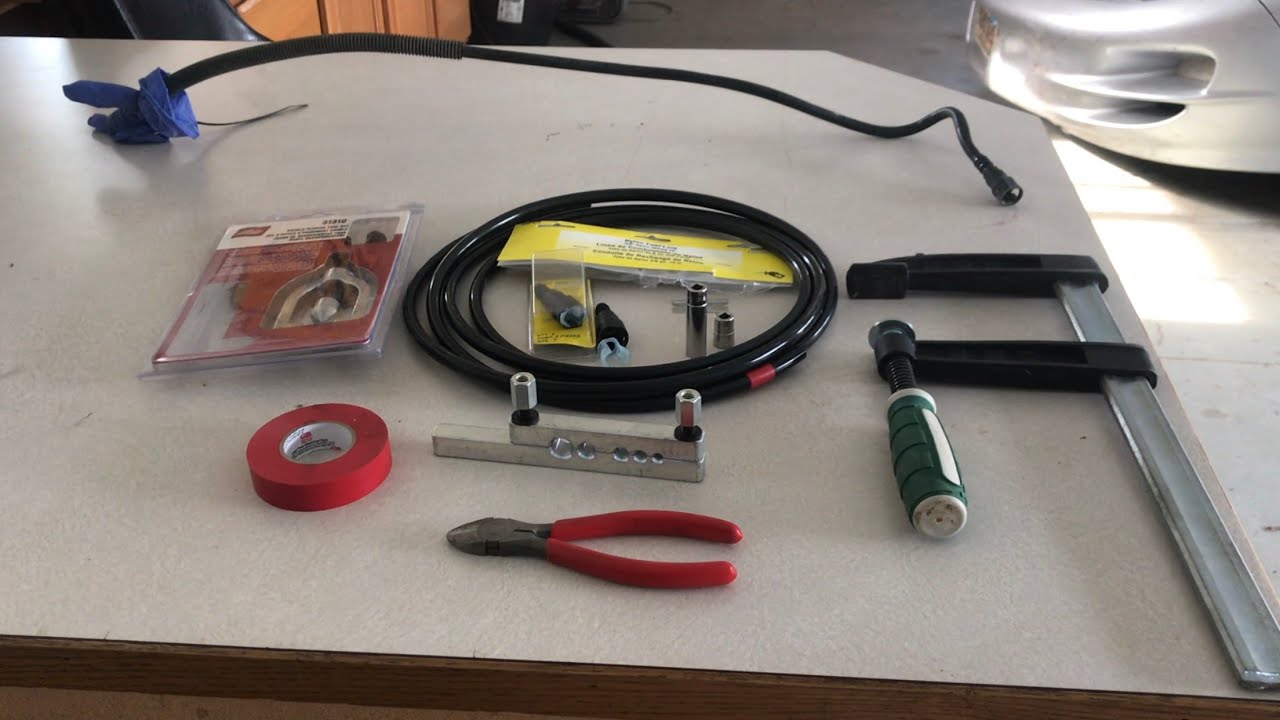

WHAT YOU’LL NEED:

Nylon fuel line

Fuel line fittings

Razor Blade

C-clamp

Brake line flare tool

Socket to fit inside fitting

Hairdryer

Vise

Side cutter

Electrical tape

I used Dorman nylon fuel line and Dorman fuel line fittings

Also this project does involve gasoline and I am not responsible for anything that you do with this information, work on your fuel lines at your own risk! Take your time and do it right, gasoline is extremely flammable!!!!!!

WHAT YOU’LL NEED:

Nylon fuel line

Fuel line fittings

Razor Blade

C-clamp

Brake line flare tool

Socket to fit inside fitting

Hairdryer

Vise

Side cutter

Electrical tape

I used Dorman nylon fuel line and Dorman fuel line fittings

Also this project does involve gasoline and I am not responsible for anything that you do with this information, work on your fuel lines at your own risk! Take your time and do it right, gasoline is extremely flammable!!!!!!

How to make nylon fuel lines the RIGHT way without the tool!

Easy Way To Make Nylon Fuel Lines

Installing Quick Connects Into Nylon Fuel Lines Gas Tank Renu

BEST ways to repair dorman nylon plastic fuel line tubing

DIY Nylon Fuel line push/quick connect

Nylon fuel line repair!

Gasoline Leak? Easy DIY Nylon Fuel Line Repair

How to install fittings into nylon fuel lines “easy way” !

Evil Energy PTFE AN Line Assembly - Yeah, It's Easy

How to repair nylon fuel lines.

How to Install a Nylon Repair Kit

How to make quick disconnect nylon fuel hose without the special tool #automobile #mechanic #diy

How to fix damaged vehicle fuel lines easier with Dorman's repair kit tech tray

Nylon Fuel Line Repair Tool

Dorman nylon fuel line tube and press unions great stuff y is no one using this odd

Making a nylon fuel line

Repairing Damaged Fuel Lines with BrakeQuip - Gear Up With Gregg's

How to Install a 90 Degree Quick Connect onto Nylon Line: FMSI

Nylon fuel line repair kit 'Repair Review'

How To Choose And Use Hardline

Electric Fuel Pump Repair & DIY Tool for Nylon Fuel line Connectors

Nylon tube pipe bending machine

How to Assemble AN, Push Loc, PTFE, Crimp Style Fittings and Hose!

nylon braided fuel line to barbed fitting hack

Комментарии

0:05:27

0:05:27

0:01:00

0:01:00

0:01:40

0:01:40

0:04:24

0:04:24

0:00:22

0:00:22

0:01:29

0:01:29

0:14:50

0:14:50

0:00:20

0:00:20

0:48:13

0:48:13

0:40:53

0:40:53

0:00:58

0:00:58

0:00:39

0:00:39

0:04:18

0:04:18

0:03:35

0:03:35

0:01:10

0:01:10

0:02:43

0:02:43

0:07:28

0:07:28

0:02:44

0:02:44

0:05:00

0:05:00

0:06:48

0:06:48

0:15:31

0:15:31

0:00:44

0:00:44

0:21:50

0:21:50

0:02:48

0:02:48