filmov

tv

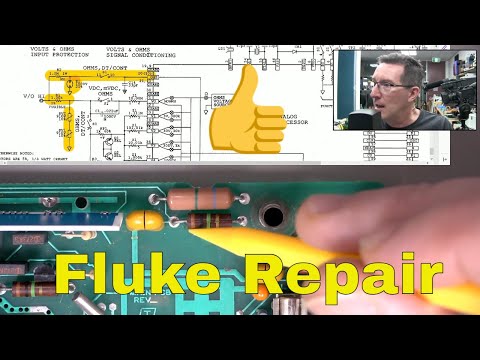

EEVblog #808 - Fluke 196 Scopemeter Repair

Показать описание

Dave repairs a dumpster Fluke 196 Scopemeter handheld oscilloscope that has a faulty LCD screen.

Forum:

How to repair a faulty hot bar LCD screen flat flex cable connection.

Support the EEVblog through Patreon!

EEVblog Amazon Store (Dave gets a cut):

Donations:

Projects:

Electronics Info Wiki:

Forum:

How to repair a faulty hot bar LCD screen flat flex cable connection.

Support the EEVblog through Patreon!

EEVblog Amazon Store (Dave gets a cut):

Donations:

Projects:

Electronics Info Wiki:

EEVblog #808 - Fluke 196 Scopemeter Repair

EEVblog #430 - Fluke 91 Scopemeter Teardown

EEVblog #791 - Ebay Fluke 45 Multimeter Teardown

EEVblog #1012 - Best Bargain Ebay Bench Meter? - Fluke 8842A

EEVblog 1425 - Fluke Repair 2 Electric Boogaloo

EEVblog #417 - Fluke CNX3000 Wireless Multimeter Teardown

EEVblog 1393 - Retro Fluke 37 Multimeter Review & Teardown

EEVblog 1448 - Convert a Fluke 77 IV to True RMS for 10 CENTS!*

EEVblog 1424 - Fluke 23 Multimeter Repair

EEVblog 1447 - EXPENSIVE Fluke vs CHEAPER Brymen - Teardown

EEVblog #372 - Fluke 27 Multimeter Review & Teardown

EEVblog #185 - Fluke 87V Multimeter GSM Fix!

EEVblog #60 - Fluke 117 Multimeter Review and Teardown

EEVblog #802 - Mailbag

Guest Video: The Defpom - Fluke Calibrator Repair

EEVblog #66 - Death & Destruction of a Fluke Multimeter

FLUKE BP190

EEVblog #807 - Mailbag

eevBLAB #44 - Sonos Deliberately Bricking Products!

Fluke 190C series ScopeMeter Firmware Upgrade, 196C

EEVblog #829 - Siglent SDM3055 Bench Multimeter Teardown

EEVblog #64 - Fluke 28 Series II Multimeter Review & Teardown

EEVblog 1377 - The Amazing UNPREDICTABILITY of Fuses!

EEVblog #688 - How To Rework Solder SMD Chips - BTTF Time Circuits Repair!

Комментарии

0:31:12

0:31:12

0:39:22

0:39:22

0:33:04

0:33:04

0:21:20

0:21:20

0:24:56

0:24:56

0:41:43

0:41:43

0:19:35

0:19:35

0:23:26

0:23:26

0:21:56

0:21:56

0:29:35

0:29:35

0:32:38

0:32:38

0:17:18

0:17:18

0:20:08

0:20:08

0:49:48

0:49:48

0:19:04

0:19:04

0:16:48

0:16:48

0:00:31

0:00:31

0:38:57

0:38:57

0:09:53

0:09:53

0:06:31

0:06:31

0:27:32

0:27:32

0:26:25

0:26:25

0:34:09

0:34:09

0:24:52

0:24:52