filmov

tv

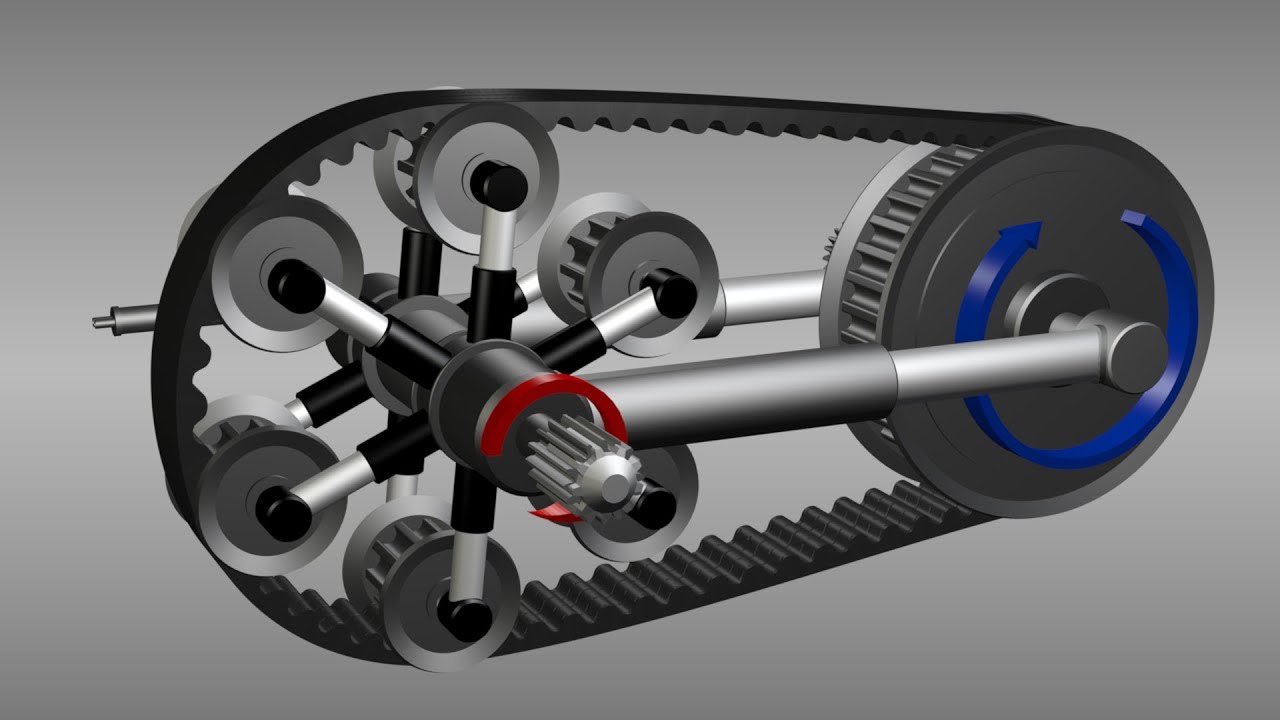

Continuously variable transmission

Показать описание

Continuously variable transmission

variable gearbox-hydraulic

variable gearbox-hydraulic

Subaru Lineartronic Continuously Variable Transmission (CVT)

Understanding CVT !

Are There Any Good CVT's? | Different CVT Transmissions Explained

Direct Shift-CVT: A New Type of Continuously Variable Transmission

This is a What a CVT Transmission Feels Like on New Nissan’s!!! #shorts

Should You Buy a CVT Transmission Car (How It Works)

Nissan X-Tronic CVT (Continuously Variable Transmission)

Are CVT Transmissions Reliable? The Truth About CVTs (Good And Bad)

Continuously Variable Transmission #transmission #automatic #electriccar #trendingshorts #trending

CVT gearbox mechanism 👍👍👍👍👍👍👍👍

How To Drive A CVT Transmission Car-Easy Tutorial

CVT Transmission / how does it work? (3d animation)

2013 Nissan Pathfinder CVT (Continuously Variable Transmission)

CVT Transmission Pros and Cons: Shocking Facts

The Subaru WRX Proves Everyone Wrong About CVT Transmissions

Comparing Manual Transmission with Automatic & CVT [In Detail]

What's The Fastest Transmission? Don't Hate The CVT!

Lineartronic Continuously Variable Transmission

2013 Nissan Altima Next Generation CVT (Continuously Variable Transmission)

Toyota's Continuously Variable Transmission (CVT)

Understanding CVT Transmissions | How CVT works?

Why Most CVT Transmission Cars are Terrible

Continuously Variable Transmission (CVT)

EN | Bosch Continuously Variable Transmission

Комментарии

0:01:15

0:01:15

0:04:44

0:04:44

0:16:17

0:16:17

0:01:03

0:01:03

0:00:55

0:00:55

0:04:44

0:04:44

0:02:36

0:02:36

0:11:56

0:11:56

0:00:22

0:00:22

0:00:21

0:00:21

0:05:16

0:05:16

0:05:31

0:05:31

0:02:36

0:02:36

0:04:00

0:04:00

0:16:39

0:16:39

0:12:10

0:12:10

0:00:52

0:00:52

0:01:27

0:01:27

0:02:35

0:02:35

0:02:09

0:02:09

0:02:15

0:02:15

0:06:20

0:06:20

0:03:17

0:03:17

0:01:57

0:01:57