filmov

tv

3D print to METAL (easier than you think)

Показать описание

Did you know its actually easy to make detailed solid metal parts from a 3D printed part at home? Sand cast 3D printed parts out of pewter using delft clay and a hand held electric heater.

___

Products used in this video:

(aff. links)

___

Happy printing!

-Steven

3D Printer Academy

___

Products used in this video:

(aff. links)

___

Happy printing!

-Steven

3D Printer Academy

The Studio System™ - Easy, Safe, Cost-Effective Metal 3D Printing

BCN3D Explains: Metal 3D printing made easy

How to Succeed with 3D Printing Metal on a Desktop 3D Printer using BASF Ultrafuse 316L Filament

Metal 3D Printer

Metal coating 3D printed parts. #3dprinting #science #art

3D print to METAL (easier than you think)

DIY Metal 3D Printer #engineering #3dprinting

This 3d printer makes metal!

Polyoxymethylene Beyblade Upgrade!

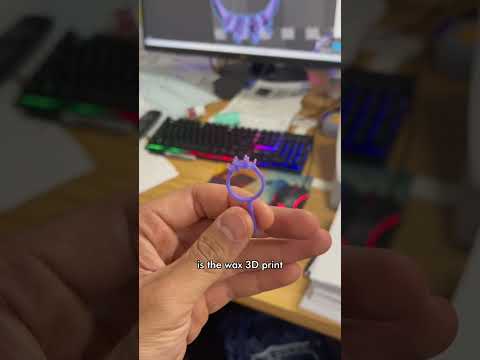

How 3D printing works in the Jewelry industry

Amazing 3D Printed Metal Parts!

Turning plastic 3D Prints into Metal Parts ⚙

Turn your 3D prints into METAL! Full sand casting guide

3D Print Metal Shine Mastery: How to Achieve Realistic Metallic Finish on Mandalorian Shoulder Armor

How to connect 3D Printed Parts!

3D Printing Metal: How strong is it?

METAL 3D printed Chainmail🤯

Multiplanar Metal 3D Printing

Let's 3D Print Some Metal, The Easy Way!!

Will A 3D Printed Quarter Work In A Gumball Machine? #shorts

$150,000 Metal 3D Printer 🤯 #3dprinter #3dprinting #shorts

YOU CAN PRINT METAL NOW?! 😱 #meltio #engineering #3dprinting

Metal Casting - Casting a 3D Printed Part 👍SUBSCRIBE!!!👍 #diy #metalcasting

7 Simple Design Tips for Metal 3D Printing | Some Serious Engineering - Ep7

Комментарии

0:04:07

0:04:07

0:03:11

0:03:11

0:07:54

0:07:54

0:00:44

0:00:44

0:00:58

0:00:58

0:04:21

0:04:21

0:00:30

0:00:30

0:00:15

0:00:15

0:01:07

0:01:07

0:00:33

0:00:33

0:00:38

0:00:38

0:01:00

0:01:00

0:06:57

0:06:57

0:01:01

0:01:01

0:00:41

0:00:41

0:01:00

0:01:00

0:00:33

0:00:33

0:00:08

0:00:08

0:00:16

0:00:16

0:00:30

0:00:30

0:00:24

0:00:24

0:00:49

0:00:49

0:01:00

0:01:00

0:09:25

0:09:25