filmov

tv

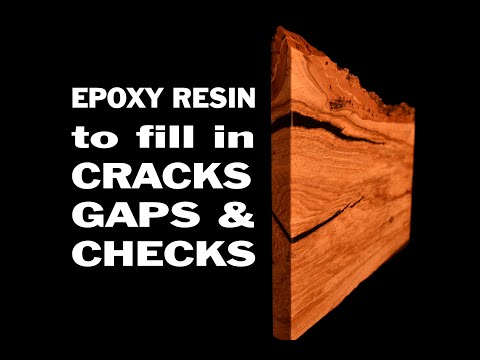

How to fill cracks and voids with epoxy resin

Показать описание

I wanted to make a quick video for you guys using the things that I've learned along the way about filling cracks, voids and knots with Epoxy resin. It's a great way to stabilize the wood and create a nice flat surface. It's also a great design feature in my opinion to incorperate into your woodworking. Enjoy!

Tools and materials used in this video:

FILMING EQUIPMENT

Other things you might find useful!

Social media:

Website:

Tools and materials used in this video:

FILMING EQUIPMENT

Other things you might find useful!

Social media:

Website:

Beginner Wood Filling Mistakes | How to Fill Cracks and Gaps

How to properly FILL CRACKS around Window Sills

WOOD REPAIR… SIMPLE methods to fix CRACKS & KNOTS // woodworking tools

How to fill cracks and voids with epoxy resin

How to Fill Cracks in Render

How to Fill Cracks & Voids with Epoxy Resin (for first-timers)

See how Easily you can repair WOOD Cracks & Knots

How to Fill, Seal, and Repair Cracks in Concrete | Concrete Repair

BIGGEST CRACKS In The Earth

Don’t Make These Errors! Sealing Small Concrete Cracks Correctly

How To Fill Cracks and Holes In Walls Before Painting - Tutorial

Better Than Wood Filler! || Great Method For Fixing Checks and Cracks

How to Repair Hairline Cracks

How to permanently repair hairline cracks in wall & ceiling plaster – DIY decorating guide

How to repair or fill small or hairline cracks in cement render walls.

How to fill in gaps and cracks - coving, baseboards, cornice and trim

How to repair cracks in rendered walls

How To Fill Cracks And Air Bubbles In Wood FAST!!! CA GLUE

Using Epoxy Resin to Fill Cracks and Gaps in Wood - Complete Tips and Techniques

How to Fill Wall Chases, Cracks & Holes

Filling cracks in masonry wall

How To Fill Asphalt Gaps and Cracks - Ace Hardware

Repairing Recurring Wall Cracks | Filling Deep Cracks | XDIY

How to Fill Driveway Cracks - Driveway Crack Filler

Комментарии

0:15:30

0:15:30

0:15:29

0:15:29

0:06:56

0:06:56

0:05:11

0:05:11

0:18:35

0:18:35

0:04:35

0:04:35

0:06:56

0:06:56

0:08:35

0:08:35

0:17:39

0:17:39

0:08:38

0:08:38

0:04:36

0:04:36

0:05:15

0:05:15

0:04:41

0:04:41

0:06:54

0:06:54

0:03:30

0:03:30

0:02:19

0:02:19

0:01:24

0:01:24

0:03:43

0:03:43

0:15:39

0:15:39

0:21:03

0:21:03

0:01:33

0:01:33

0:02:22

0:02:22

0:03:11

0:03:11

0:04:49

0:04:49