filmov

tv

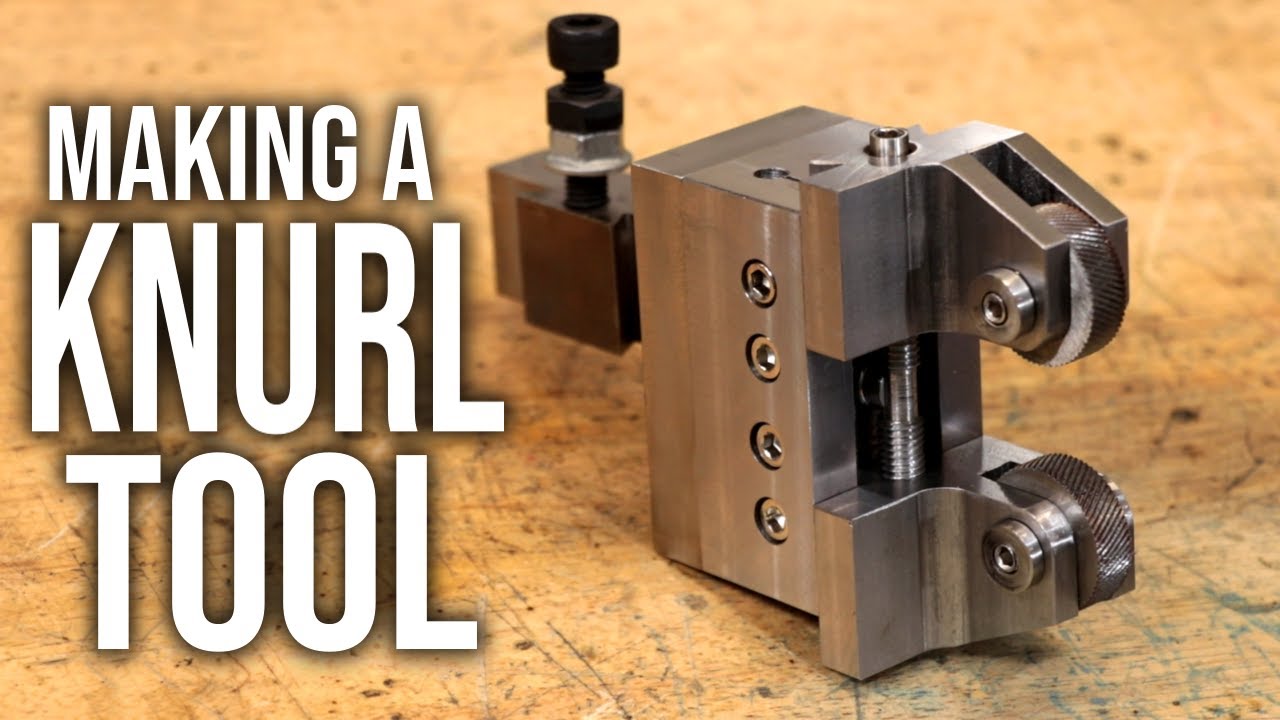

Making A Knurling Tool For The Lathe

Показать описание

G'day everyone,

Fore the last project of the year I thought I might as well get around to doing a project that has been on my list for quite some time. And that is to make a new knurling tool. My old one is a bump style (or push type) knurler and whilst they are great for larger lathes, they do require quite a lot of force to use, and according to the machining zeitgeist, that is very bad for the spindle bearings.

The new style that I will make is a clamp style. It will use a screw to clamp the two pattern wheels on to the workpiece, which should save the spindle bearings. This seems to be quite similar to a scissor type knurl tool and I have no idea if there is an advantage to one type. All I know is the clamp style works and it works well. I hope you enjoy the video

Lathe - Hafco Al250g

Mill - Sieg x2.7l

#machining #diy #lathe

Timestamps

0:00 - Intro

2:17 - Making The Main Body

5:36 - Making The Roller Arms

12:25 - Making A M8 x 1.25 Left Hand Tap

18:54 - Making The Leadscrew

21:26 - Making The Roller Pins

23:38 - Making The Backplate

25:05 - Final Assembly and Testing

Fore the last project of the year I thought I might as well get around to doing a project that has been on my list for quite some time. And that is to make a new knurling tool. My old one is a bump style (or push type) knurler and whilst they are great for larger lathes, they do require quite a lot of force to use, and according to the machining zeitgeist, that is very bad for the spindle bearings.

The new style that I will make is a clamp style. It will use a screw to clamp the two pattern wheels on to the workpiece, which should save the spindle bearings. This seems to be quite similar to a scissor type knurl tool and I have no idea if there is an advantage to one type. All I know is the clamp style works and it works well. I hope you enjoy the video

Lathe - Hafco Al250g

Mill - Sieg x2.7l

#machining #diy #lathe

Timestamps

0:00 - Intro

2:17 - Making The Main Body

5:36 - Making The Roller Arms

12:25 - Making A M8 x 1.25 Left Hand Tap

18:54 - Making The Leadscrew

21:26 - Making The Roller Pins

23:38 - Making The Backplate

25:05 - Final Assembly and Testing

Комментарии

0:27:12

0:27:12

0:20:16

0:20:16

0:22:11

0:22:11

0:04:55

0:04:55

0:31:54

0:31:54

0:12:02

0:12:02

0:23:23

0:23:23

0:24:09

0:24:09

0:08:00

0:08:00

0:14:40

0:14:40

0:14:48

0:14:48

0:21:22

0:21:22

0:20:48

0:20:48

0:05:47

0:05:47

0:10:13

0:10:13

0:00:28

0:00:28

0:23:19

0:23:19

0:12:04

0:12:04

0:08:51

0:08:51

0:09:32

0:09:32

0:26:55

0:26:55

0:14:47

0:14:47

0:14:23

0:14:23

0:12:05

0:12:05