filmov

tv

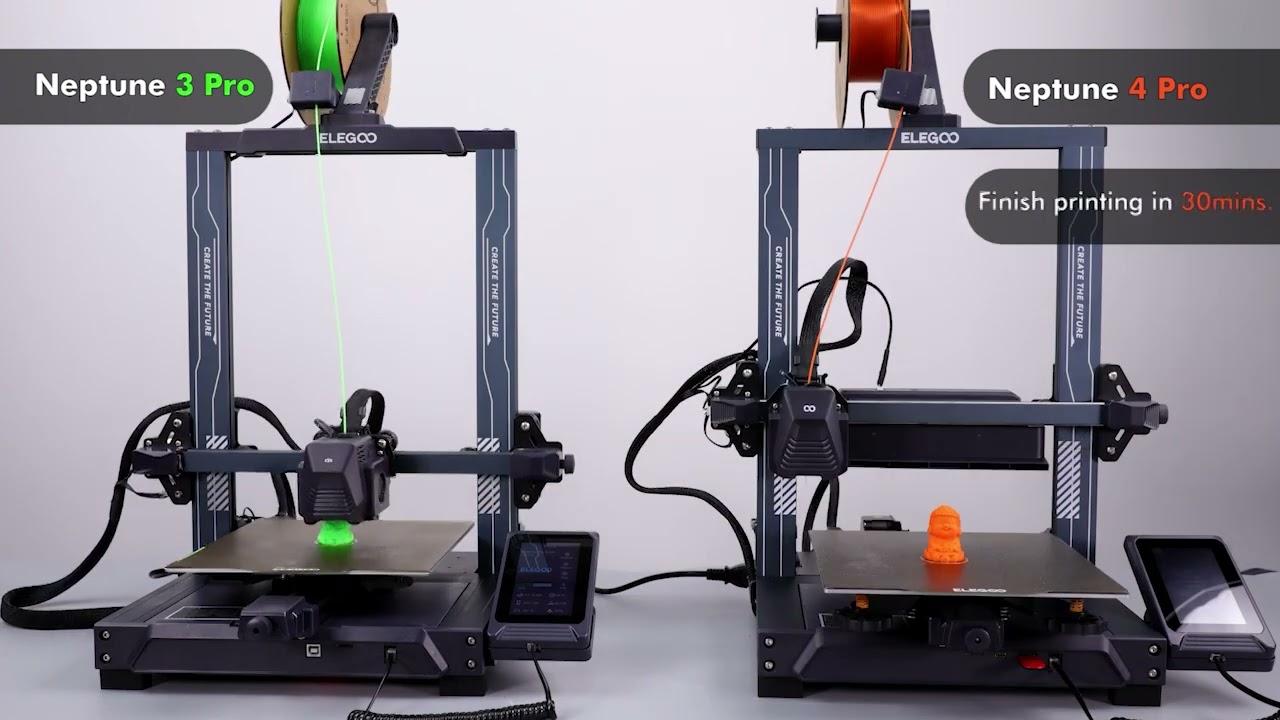

Speed Comparison: Neptune 3 Pro VS Neptune 4 Pro

Показать описание

With the Klipper motherboard and ARM 64-bit 1.5G main frequency quad-core processor to process and execute commands faster, Neptune 4 Pro can print at up to 500mm/s, allowing you to complete your print projects quickly and efficiently. With our pre-installed Klipper firmware, you can start printing right away without the hassle of firmware installation.

In addition, it supports input shaping, which helps eliminate artifacts and resonances on the model surface, and pressure advance, which helps predict nozzle pressure for more accurate and consistent extrusion and less filament ooze and blobbing.

.

.

.

In addition, it supports input shaping, which helps eliminate artifacts and resonances on the model surface, and pressure advance, which helps predict nozzle pressure for more accurate and consistent extrusion and less filament ooze and blobbing.

.

.

.

Speed Comparison: Neptune 3 Pro VS Neptune 4 Pro

Neptune 3 Pro vs. Neptune 4 Pro Speed Comparison #3dprinting #shorts #3dprinter #youtubeshorts

Speed Comparison Neptune 3 Pro VS Neptune 4 Pro - Antinsky3d

Speed vs. Quality: Elegoo Neptune 4 vs. Prusa MK3S+

Elegoo Neptune 3 Pro vs Elegoo Neptune 4

Elegoo Neptune 3 - Pro vs Plus vs Max

Bambu Labs vs Elegoo Neptune speed comparison.

Elegoo Neptune 3 Pro & Plus: 250mm/s high speed printing, stock Marlin VS Creality Sonic pad Kli...

June 2024 Earth Science Regents, PREPARE for the August 2024 Earth Science Regents! - JuanTutors

Ender 3 Pro vs Neptune 3 Pro & Plus vs Bambu Lab P1P

Neptune 3 pro and Neptune 4 speed side by side

Elegoo Neptune 3 PRO - Honest Review + Timelapse Mod

A DIRECT DRIVE Elegoo Neptune 3?? Meet the new Neptune 3 PRO!

Elegoo Neptune 3 MAX VS Creality CR-M4! Can $470 beat $1100??

Elegoo Neptune 3 Plus Speed Benchy! 12.5m, full proof coming soon! Bambu Voron Hotend #speedboatrace

Stop 3d printing so slow!!! 🤯 (how to print faster)

Elegoo Neptune 3 - Pro Plus Max

Elegoo Neptune 4 & 4 Pro Review - A printer SO FAST it was rushed to market

Squishy 3D Prints - Elegoo Neptune 3 Pro 3D Printer

How FAST is KLIPPER REALLY? ...CHEAP BED SLINGERS go Ferrari mode?

Elegoo Neptune 4 vs Bambu Lab P1P print speed race.

First 5 Upgrades for the Elegoo Neptune 3 Pro

ELEGOO Neptune 3 Pro vs Neptune 4 Plus 3D Printer Comparison 🆚🖨️

Sovol SV06 or Elegoo Neptune 3 Pro? Which should you buy? Features compared!

Комментарии

0:00:27

0:00:27

0:00:27

0:00:27

0:00:27

0:00:27

0:01:00

0:01:00

0:10:13

0:10:13

0:09:27

0:09:27

0:00:34

0:00:34

0:24:34

0:24:34

5:19:35

5:19:35

0:00:56

0:00:56

0:00:22

0:00:22

0:14:01

0:14:01

0:14:05

0:14:05

0:17:31

0:17:31

0:00:14

0:00:14

0:04:14

0:04:14

0:00:16

0:00:16

0:12:41

0:12:41

0:11:59

0:11:59

0:10:04

0:10:04

0:00:39

0:00:39

0:01:44

0:01:44

0:05:24

0:05:24

0:06:40

0:06:40