filmov

tv

How To Connect Two Ends Of A Timing Belt In 58 Seconds

Показать описание

#Shorts

A very simple and useful way to connect two ends of a timing belt. Whether its for a 3D printer, Laser or home made invention. This video will show you how for only a couple of pennies you can connect two ends of a timing belt just as strong as a professional product.

If you have any questions or want us to make/do something please

leave us a comment.

Music:

A very simple and useful way to connect two ends of a timing belt. Whether its for a 3D printer, Laser or home made invention. This video will show you how for only a couple of pennies you can connect two ends of a timing belt just as strong as a professional product.

If you have any questions or want us to make/do something please

leave us a comment.

Music:

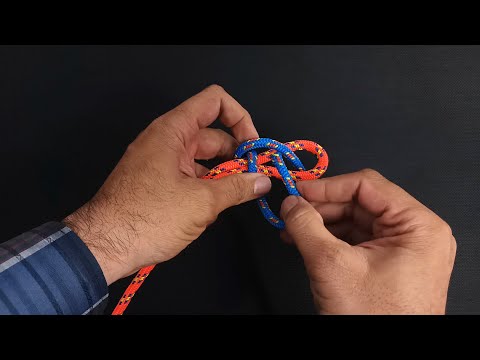

Easily Connect 2 Ropes Together!

How To Tie Two Strings Together - Most Usefull Knots in Life (p2) #shorts

How to Tie Two Ropes Together #shorts

How to join yarn with a magic knot

Joining Bias Strips. How to Connect two Ends of Bias Tape

A skill that EVERYONE should know!

SIMPLE TIP TO TIE COPPER WIRES

How to solder two wires together | Crutchfield

How To Connect Two Ends Of A Timing Belt In 58 Seconds

How To Connect Two Ends Of A Timing Belt Together - Super Simple

How to tie a Uni to Uni Knot - Connecting two fishing lines together

Super strong invisible yarn join #crochet #crochettutorial #easycrochet #yarn #yarnlove

Part 2: Absolutely Secure Knot to Use 🪢

How To Tie The Alberto Knot In Under 50 Seconds #Shorts

Learn How to Join Yarn in 30 Seconds - Quick Crochet Tutorial #shorts

How to tie a simple and practical knot to connect two ends of a rope #viral #viralvideo #viralshorts

electrician tips: how to joint electric wires

Two Ropes. One Strong Knot. Zero Hassle.

Basic Knot To Connect Two Ends

How to connect two ends of twisted, cotton decorative rope together without unraveling

Brilliant Last Binding Join For Your Quilt

How to tie a simple and practical knot to connect two ends of a rope #viral #viralvideo #viralshorts

How to Connect Two Ends of a Metal Chain | DIY Tools

How to tie a simple and practical knot to connect two ends of a rope #viral #viralvideo #viralshorts

Комментарии

0:00:35

0:00:35

0:00:49

0:00:49

0:00:21

0:00:21

0:00:26

0:00:26

0:02:56

0:02:56

0:00:36

0:00:36

0:00:24

0:00:24

0:01:28

0:01:28

0:00:58

0:00:58

0:02:26

0:02:26

0:01:00

0:01:00

0:00:27

0:00:27

0:00:52

0:00:52

0:00:59

0:00:59

0:00:29

0:00:29

0:02:06

0:02:06

0:00:08

0:00:08

0:00:28

0:00:28

0:00:28

0:00:28

0:01:33

0:01:33

0:00:57

0:00:57

0:01:26

0:01:26

0:01:08

0:01:08

0:01:00

0:01:00