filmov

tv

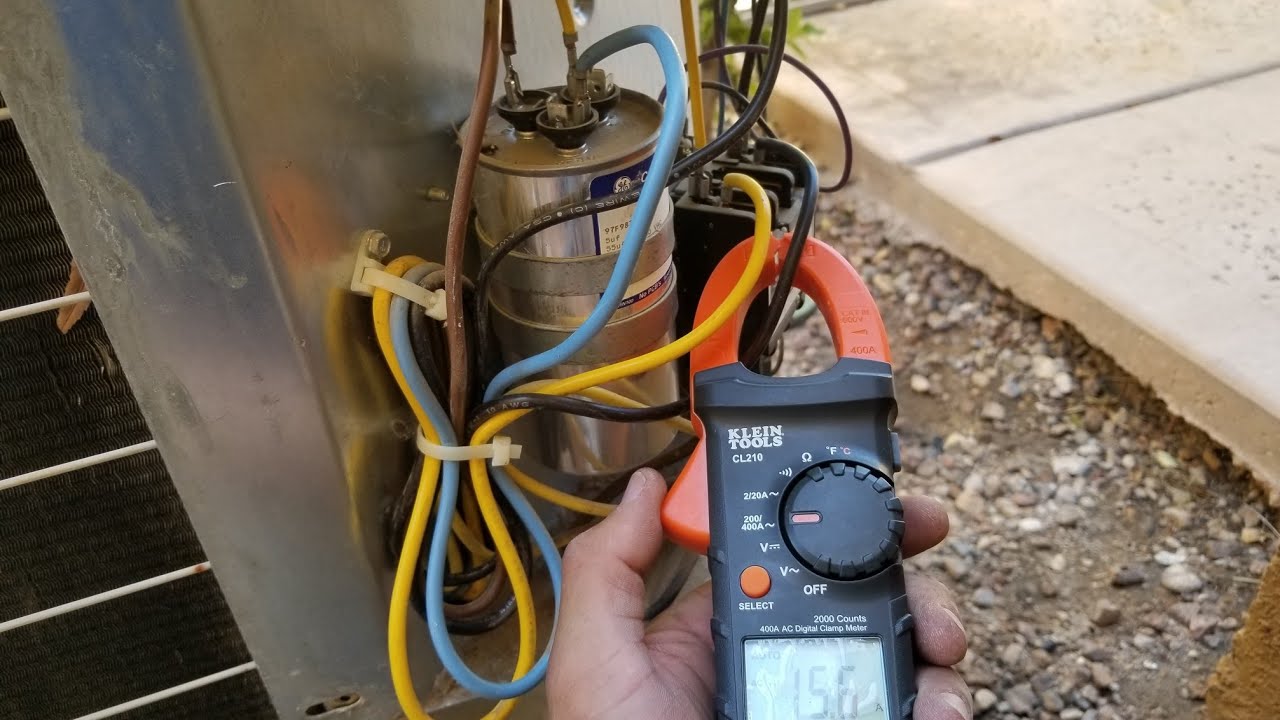

How to Check Amperage on Compressor and Fan Motor

Показать описание

This will be great in allowing you to determine if the amp draw on your compressor is causing your breaker to trip. I also included the amp draw test for the condenser fan motor. Always refer to the specs on your compressor to determine the proper amp draw for your specific system which is usually located on the identification plate on the compressor itself. When checking specs for condenser fan motor you will find the specs on the fan motor itself.

How to Check Amperage on Breaker

How To Test Amperage / Amp Draw and properly measure and fuse a circuit

Using a Digital Multimeter to Check Amperage | ACDelco TechConnect

How to Check Amperage on Compressor and Fan Motor

How To Test Electrical Wires For Amperage

How to Use a Clamp Meter: Testing Current on an Appliance

How to Check Welder Output Amperage A Simple TEST

Current / Parasitic Draw With Amp Clamp - The Best Way To Test

9 AUG 2024 Current Affairs | Current Affairs Today For All Exams | Daily Current Affairs

How to Check Alternator Amperage with Multimeter

How to check the amperage, breaker and sizing?

How to Test USB Current and Battery Bank Capacity

Barnaby @ Home: Testing Amperage

Electrical Testing Measuring Prospective Fault Current PFC (How to do a PSCC and PEFC Test)

How to Find Current Drain in a Car with a Multimeter and Clamp Meter

HOW TO CHECK 3 PHASE CURRENT LOAD

How to use amp clamp multimeter to check AC current

How to test starter current Draw

How to Check DC Battery Current with KAIWEETS Digital Multimeter | Ampere and Milliampere

DT-830B :// How to use a Digital Multimeter to test Voltage,Current and Resistance

How to check Motor Current in Schneider Atv320 VFD

How to Check AC or DC Current in Milliamp (mA) with a Digital Multimeter | KAIWEETS

How to Check AC Current Using Multimeter or Clamp Meter

Basics of Leakage Current Testing

Комментарии

0:02:56

0:02:56

0:02:54

0:02:54

0:07:40

0:07:40

0:04:08

0:04:08

0:03:34

0:03:34

0:01:48

0:01:48

0:09:36

0:09:36

0:01:12

0:01:12

0:59:55

0:59:55

0:05:41

0:05:41

0:14:17

0:14:17

0:06:02

0:06:02

0:03:40

0:03:40

0:01:47

0:01:47

0:02:45

0:02:45

0:00:52

0:00:52

0:04:18

0:04:18

0:01:36

0:01:36

0:01:48

0:01:48

0:12:21

0:12:21

0:00:39

0:00:39

0:01:37

0:01:37

0:05:30

0:05:30

0:04:13

0:04:13