filmov

tv

Can Copper Weld into Steel Damascus?

Показать описание

Instagrams:

Alec: @alecsteele

My name is Alec Steele and I am a 24 year old blacksmith. We make videos about making interesting things, learning about craft and appreciating the joy of creativity. Great to have you here following along!

Thank you for watching!

Alec

INSTAGRAM @alecsteele

MUSIC:

-signing up at this link supports the show!

- signing up at this link supports the show!

------------------------------------------------

AMAZON AFFILIATE LINKS TO GEAR I LIKE, buying here supports us:

--------------

Alec Steele Blacksmith 2022

Can Copper Weld into Steel Damascus?

CAN YOU WELD COPPER? - not solder, not braze, but weld? spoiler....yes you can and i will show you

Can you Forge Weld Copper?!!

TIG Welding Copper to Steel HOW TO

How to Weld Copper to Steel for Art - Kevin Caron

How to Weld Copper | TIG Time

Copper welding with stainless steel & different material welding by Five Laser

copper brazing#induction #welding #heating #brazing #machine

Secure Every Weld! Get the Angled Welding Clamp with Copper Core!

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

How do you TIG weld COPPER?! 🤔

Brazing Copper to Brass with Sil-Fos®

Welding vs Soldering vs Brazing - Basic Brazing Tutorial

The BEST 25 Copper Pipe Tips & Tricks EVER! | GOT2LEARN

how to weld copper pipe with aluminium pipe #shorts

Welding stainless steel to copper #welding #tig

How To Solder Copper Pipe (Complete Guide) Plumbing 101

How to weld Copper with tig

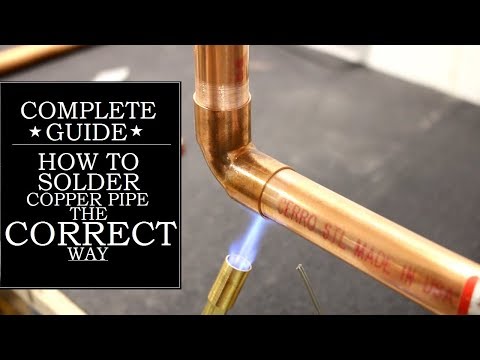

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

Connect Copper Pipe Without Solder || Joint Copper Pipe Without Brazing And Welding

5 MISTAKES Beginners Make When Soldering Copper Pipe | GOT2LEARN

Tooltip: Using Copper Welding Spoons for Filling Holes

An old method of copper welding in the 1970's

TIG Welding Copper - Making a Copper Drinking Mug

Комментарии

0:10:56

0:10:56

0:04:12

0:04:12

0:05:54

0:05:54

0:15:46

0:15:46

0:07:56

0:07:56

0:04:07

0:04:07

0:01:00

0:01:00

0:00:20

0:00:20

0:00:29

0:00:29

0:10:46

0:10:46

0:18:04

0:18:04

0:04:21

0:04:21

0:09:19

0:09:19

0:10:22

0:10:22

0:00:42

0:00:42

0:01:00

0:01:00

0:05:54

0:05:54

0:05:37

0:05:37

0:05:05

0:05:05

0:02:18

0:02:18

0:06:05

0:06:05

0:01:25

0:01:25

0:03:14

0:03:14

0:06:25

0:06:25