filmov

tv

Watch This Video Before Pouring A Concrete Foundation – Construction Tips

Показать описание

Click on this link for more videos on construction, building foundations and concrete. Here's a video I wish everyone who ever poured a concrete building foundation would watch at least once before pouring the concrete and then wondering why they had problems that could have been solved with a little information. I see this all the time and will probably see it for years to come, but once the concrete is dry, any excess bulges will probably need to be chipped away with the chipping hammer or jackhammer and this isn't going to be easy.

Watch This Video Before Pouring A Concrete Foundation – Construction Tips

FREE VIDEO FOOTAGE NO COPYRIGHT Pouring red wine from a bottle, very close view

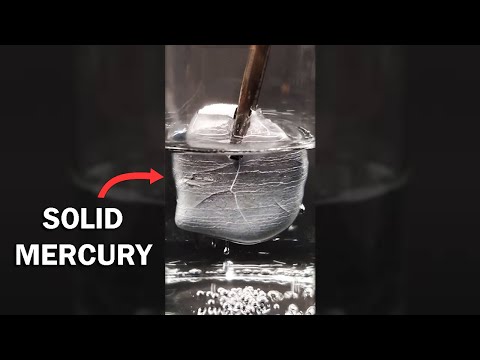

Touching mercury

My FAVORITE Acrylic Pouring Techniques Using Just Paint and Water!

Stunning videos show devastating aftermath of Hurricane Milton

Discover how to turn ordinary plastic caps into a chic handbag that’s as unique as you are! 🐢✨...

Teaspoon Trickery 💦🥄 The Splash-Free Liquid Pouring Hack You Need! #liquidfilling

(967) 200 Toothpicks | Acrylic Pouring | Just Paint and Water | Designer Gemma77

Double Check Hold Down Locations And Heights Before Pouring Concrete

Pouring Molten Hot Glass

GORGEOUS Flow 😍 ~ Coral Reef Acrylic Pouring ~ FUNNEL Pour + DUTCH Pour #SHORTS

ARE YOU POURING TOO FAST? #latteart #coffee #crema #homebarista

Multiple PAINT KISS Pour 😘 Taking this Acrylic Pouring Technique to New Level

Caught BadKidJay Sleeping Poured Water On Him🤣🤣 #shorts

Pouring lava in water

Self-Pouring Liquid

Poured Milk on Jerry 🥛 Funny Video 😅 #funnyvideo #cartoon #memes

10 Acrylic Pouring Tips and Tricks | Tips I Wish I Knew When I Started Acrylic Paint Pouring

Tower crane pouring concrete#shorts

Epoxy Resin Art Galaxy Themed | Pouring and Demolding | #epoxy #resin #shorts

Go With The Flow - acrylic pouring workshop - www.anapazartist.com

You’re pouring beer the wrong way! #shorts

Pouring mercury into liquid nitrogen

HE COULDN’T GET OUT!

Комментарии

0:07:45

0:07:45

0:00:19

0:00:19

0:00:39

0:00:39

0:14:41

0:14:41

0:28:59

0:28:59

0:00:59

0:00:59

0:00:27

0:00:27

0:05:03

0:05:03

0:04:28

0:04:28

0:00:15

0:00:15

0:00:49

0:00:49

0:00:29

0:00:29

0:07:07

0:07:07

0:00:26

0:00:26

0:00:29

0:00:29

0:00:39

0:00:39

0:00:16

0:00:16

0:11:09

0:11:09

0:00:11

0:00:11

0:01:00

0:01:00

0:01:00

0:01:00

0:01:01

0:01:01

0:01:00

0:01:00

0:00:55

0:00:55