filmov

tv

what Worked What didn't Pouring Air Crete Panels for Shed

Показать описание

Check out our shop

Check out our website:

Email

Send Mail to

Honey Do Carpenter

PO BOX 51272

Idaho Falls, ID 83405

Pinterest

Facebook

Honey Do Carpenter

As an Amazon Associate I earn from qualifying purchases.

Check out the book The 5 Love Languages: The Secret to Love that Lasts

#ad Hydrated Lime:

#ad J lube:

#ad Gloves:

#ad Glasses:

Check out our website:

Send Mail to

Honey Do Carpenter

PO BOX 51272

Idaho Falls, ID 83405

Honey Do Carpenter

As an Amazon Associate I earn from qualifying purchases.

Check out the book The 5 Love Languages: The Secret to Love that Lasts

#ad Hydrated Lime:

#ad J lube:

#ad Gloves:

#ad Glasses:

what Worked What didn't Pouring Air Crete Panels for Shed

When Concrete Pouring Goes Totally Wrong!

Concrete Catastrophe (didn't Dig grass out & poured over it anyways)

You’re pouring beer the wrong way! #shorts

Pouring Concrete at the WRONG HOUSE 'WOOPS' (idiota)

Biggest Gravel Driveway Mistake People Make! #graveldriveway

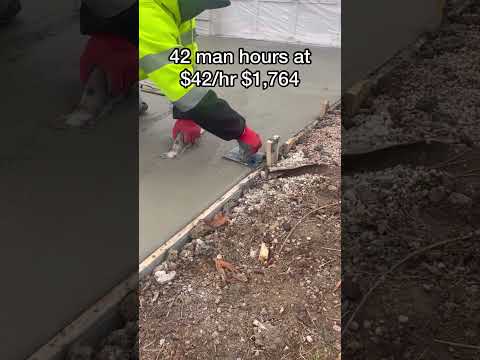

How I priced this $7,000 driveway 🔥

Is Nasal Irrigation safe? #doctor #shorts

Something doesn’t feel right about this.. 🤔 #concrete #construction #work #cdl #trucking #readymix...

I Can’t Believe I Guessed Her Name 😅

Here's A Drain Cleaner That REALLY Works

Jiggliest water slime ever?!?? 💦 #waterslime #aprilfools

Why don't you install the electrical conduits before pouring the concrete#construction #electri...

Gross nasal rinse ✌️ #doctor

Epoxy Resin art is on another level😻 #craft #resinart #resin #resinartist #glitter #decorative #diy...

Post in Concrete -Do you not believe me??? #diy

I wonder if he fired the guy who measured😬🎰#concrete #construction #work #cdl #trucking #business...

No demolition of the roof concrete formwork- Good tools and machinery make work easy

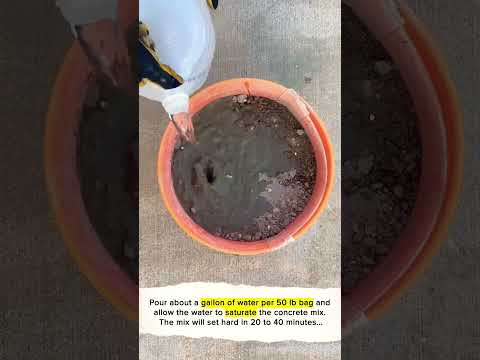

Have you ever tried Quikrete’s fast setting concrete mix?

What happens if you drink bleach ? 😮 [EXPLAINED]

FAKE WATER CUP PRANK ON MY LITTLE SISTER 🤣 #shorts

cold water 🥶 but not for all 😂 #shorts

Is YOUR Coolant Going Down But NO Leak | Bad radiator CAP Signs | #Shorts

Concrete Catastrophe (poured Concrete directly on grass) FIBER-GRASS REINFORCEMENT

Комментарии

0:09:25

0:09:25

0:00:53

0:00:53

0:00:33

0:00:33

0:01:01

0:01:01

0:00:25

0:00:25

0:00:54

0:00:54

0:00:23

0:00:23

0:00:15

0:00:15

0:00:27

0:00:27

0:00:32

0:00:32

0:00:40

0:00:40

0:00:12

0:00:12

0:00:40

0:00:40

0:00:13

0:00:13

0:00:16

0:00:16

0:00:24

0:00:24

0:00:38

0:00:38

0:00:07

0:00:07

0:00:50

0:00:50

0:00:32

0:00:32

0:00:23

0:00:23

0:00:06

0:00:06

0:00:40

0:00:40

0:00:43

0:00:43