filmov

tv

EEVblog #1253 - LED Flicker 2: Electric Boogaloo

Показать описание

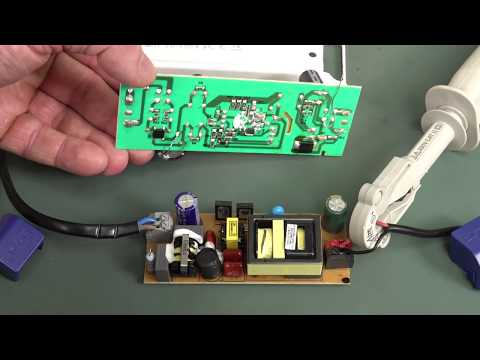

Part 2 of the LED Flicker investigation.

Modding the driver for input and output capacitance and it's effect on power factor correction and thermal performance.

#LED #Flicker

Bitcoin Donations: 38y7DE8HEHNj8fGDtUr4PkCn9nWxiorvvy

Litecoin: ML7oQokTwB38bgzzjLDbRV97HKAHuwRfHA

Ethereum: 0x11AceA38DCA9DbFfB4F35f3F746af65F9dED28ce

Support the EEVblog through Patreon!

Buy anything through that link and Dave gets a commission at no cost to you.

Stuff I recommend:

Donate With Bitcoin & Other Crypto Currencies!

Modding the driver for input and output capacitance and it's effect on power factor correction and thermal performance.

#LED #Flicker

Bitcoin Donations: 38y7DE8HEHNj8fGDtUr4PkCn9nWxiorvvy

Litecoin: ML7oQokTwB38bgzzjLDbRV97HKAHuwRfHA

Ethereum: 0x11AceA38DCA9DbFfB4F35f3F746af65F9dED28ce

Support the EEVblog through Patreon!

Buy anything through that link and Dave gets a commission at no cost to you.

Stuff I recommend:

Donate With Bitcoin & Other Crypto Currencies!

EEVblog #1253 - LED Flicker 2: Electric Boogaloo

EEVblog #1252 - LED Panel Lighting Flicker Investigated

LED Flicker 3 - More Electric Boogaloo

EEVblog #765 - LED Panel Lighting Switching Noise

EEVblog #1261 - Dumpster Diving 55' LCD TV

EEVblog #1238 - Vion: The World's Worst Multimeter!

EEVblog #1251 - LifeSaber Kickstarter - A Master of None FAIL

LED Flicker Test 3

Utra-Slim Flicker Free led driver

Flickering LEDs - Aliasing, Cameras, and LEDs | DMX 1

EEVblog #1262 - Designing a Flex PCB + uSupply Update

EEVblog #1277 - Electric Fence Controller Teardown

LED lamp flicker test + typical circuit diagrams

Jolt the Volt: How Voltage Drop Can Affect Your LED Signs - Episode 6

eevBLAB #64 - Tesla Solar City Panels Are CATCHING ON FIRE!

EEVblog #1267 - How To Control a 747 Flight Simulator

EEVblog #1241 - Power Up Display Counter Project - Part 1

EEVblog #56 - Agilent U1253A OLED Multimeter Review & Teardown

EEVblog #1230 - How The Apollo 11 Moon Walk Video Happened

EEVblog #1194 - 1985 Electronics

Why does my LED lamp flash? - flickering, flashing, strobing

EEVblog #1256 - GORGEOUS Mystery Test Gear Teardown!

60W IP20 Constant Voltage LED Power Supply , Plastic Flicker Free Driver

Flicker and Power-Line Frequency - Friday Minis 38

Комментарии

0:21:27

0:21:27

0:19:34

0:19:34

0:08:08

0:08:08

0:06:19

0:06:19

0:11:29

0:11:29

0:39:34

0:39:34

0:28:49

0:28:49

0:00:34

0:00:34

0:00:24

0:00:24

0:10:53

0:10:53

0:55:19

0:55:19

0:19:44

0:19:44

0:07:01

0:07:01

0:02:02

0:02:02

0:11:04

0:11:04

0:25:35

0:25:35

0:36:43

0:36:43

0:27:35

0:27:35

0:19:57

0:19:57

0:21:27

0:21:27

0:03:55

0:03:55

0:29:26

0:29:26

0:00:31

0:00:31

0:03:29

0:03:29