filmov

tv

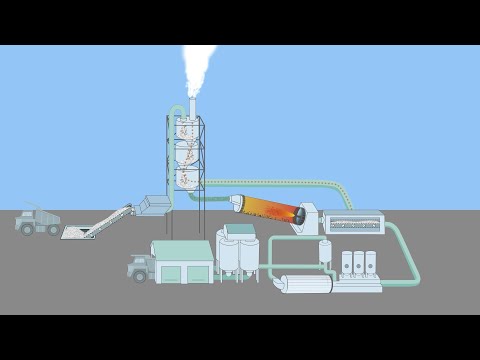

How CEMENT is Made

Показать описание

How CEMENT is Made

Welcome to Factora!

Join us on a fascinating journey as we explore the captivating world of creation and unveil the secrets behind how things are made.

Each video is a mesmerizing showcase of the intricate processes that bring everyday objects to life. From the manufacturing of technological marvels to the creation of delicious culinary delights, we leave no stone unturned in our quest to reveal the artistry and ingenuity that go into making the things we use and enjoy.

Whether you're passionate about engineering, design, or simply curious about the world around you, our channel offers a captivating blend of education and entertainment.

#factora #factory #howthingsaremade

Welcome to Factora!

Join us on a fascinating journey as we explore the captivating world of creation and unveil the secrets behind how things are made.

Each video is a mesmerizing showcase of the intricate processes that bring everyday objects to life. From the manufacturing of technological marvels to the creation of delicious culinary delights, we leave no stone unturned in our quest to reveal the artistry and ingenuity that go into making the things we use and enjoy.

Whether you're passionate about engineering, design, or simply curious about the world around you, our channel offers a captivating blend of education and entertainment.

#factora #factory #howthingsaremade

How CEMENT is Made

How Cement Is Made? (Mega Factories Video)

How CEMENT is Made | in FACTORIES

How Cement is Made

How Cement is made? Dry process

How it's Made Cement | Mega Cement Factory

Scientists Finally Know How Roman Concrete Was Made

How Cement is Made?

How to make a pot with clay | Cement craft ideas | DIY do it your own #diy #flowerpot #handmade

Wet process for portland cement manufacturing

Manufacturing of Portland Cement

I buried myself in concrete to explain how it works

Cement Manufacturing | Limestone Mining to Packaging Unit

How is Concrete made? 🛣 Maddie's Do You Know 👩

The big problem with cement, and how to fix it

You Won't Believe How Cement Is Made in the Factory - Incredible Technology

How Concrete is Made

How it's made - Handmade Cement Tiles

How it's made - Handmade Cement Tiles

How cements are manufactured in factory 🏭 so satisfying process [3d animation] ,full documentary

How Cement is Made?

How Cement is Made Step by Step Introduction into the world of Cement Production

What is Concrete?

How Cement is Made: Inside a Cement Factory - Did You Know?

Комментарии

0:07:36

0:07:36

0:08:04

0:08:04

0:08:15

0:08:15

0:05:51

0:05:51

0:01:25

0:01:25

0:08:26

0:08:26

0:01:00

0:01:00

0:04:00

0:04:00

0:07:28

0:07:28

0:01:54

0:01:54

0:10:05

0:10:05

0:00:59

0:00:59

0:00:21

0:00:21

0:05:47

0:05:47

0:08:11

0:08:11

0:08:05

0:08:05

0:00:45

0:00:45

0:00:31

0:00:31

0:00:50

0:00:50

0:05:43

0:05:43

0:07:12

0:07:12

0:06:01

0:06:01

0:09:11

0:09:11

0:07:05

0:07:05