filmov

tv

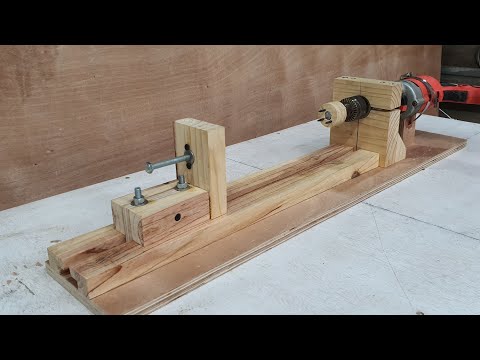

DIY Drill Powered Lathe

Показать описание

Make your own drill powered lathe!

Have a question? Hit me up on social media:

Facebook & Instagram: @oneminuteworkbench

Twitter: @oneminworkbench

Drill Used: DeWalt D21008

Have a question? Hit me up on social media:

Facebook & Instagram: @oneminuteworkbench

Twitter: @oneminworkbench

Drill Used: DeWalt D21008

DIY Drill Powered Lathe

Build a DIY drill powered lathe, does it really work?

Simple Portable Lathe | Japanese Woodworking

How To Make Homemade Lathe Machine Using Drill Machine | Diy Metal Lathe Machine | DIY

I Tried the Cheapest Lathe on the Internet

Homemade Woodworking Lathe || Make A Drill Powered Wooden Lathe

Homemade DIY Drill Lathe v2.0

How to make a mini lathe in 10 minutes

Vevor Magnetic Drill Press. 5/16 hole. #fabrication #machining

Unboxing Drill Lathe for Wood Turning

How to Make a Simple Drill Powered Lathe machine at Home | DIY .2020

How To Make a Drill Lathe

9 Best Drill Hacks | DIY Woodworking

DIY: How to make a wood lathe powered by electric drill | Homemade Woodworking Lathe Machine

Make Hand Drill Lathe| DIY The Simplest Lathe.

How to make a homemade wooden lathe - Drill powered wooden lathe

Homemade Lathe Machine From PVC pipe

Top 4 Best Mini Metal Lathe Machines

3 in 1 Homemade Lathe Machine. Part 1 - Drill Powered Wooden Lathe

USE Hand Drill Lathe| DIY Hyacinth with Homemade Lathe

DIY Drill Powered Disc Sander

DIY Amazing mini Lathe machine using Drill only | Wood Craft | #shorts #diy #tools #tips #how

Test MINI LATHE MACHINE For Woodworking DIY

Build a DIY drill powered lathe - Part 2, does it really work?

Комментарии

0:12:33

0:12:33

0:09:44

0:09:44

0:08:09

0:08:09

0:25:26

0:25:26

0:11:06

0:11:06

0:13:05

0:13:05

0:00:09

0:00:09

0:06:00

0:06:00

0:00:52

0:00:52

0:06:40

0:06:40

0:06:20

0:06:20

0:03:58

0:03:58

0:21:58

0:21:58

0:18:56

0:18:56

0:15:05

0:15:05

0:18:05

0:18:05

0:43:12

0:43:12

0:26:20

0:26:20

0:19:11

0:19:11

0:09:18

0:09:18

0:15:17

0:15:17

0:00:17

0:00:17

0:04:31

0:04:31

0:06:52

0:06:52