filmov

tv

Watch this before using polyurethane wood finish!

Показать описание

▼EXPAND THIS SECTION FOR MORE RESOURCES RELATED TO THIS VIDEO▼

★THIS VIDEO WAS MADE POSSIBLE BY★

*Please help support us by using the link above for a quick look around!*

(If you use one of these affiliate links, we may receive a small commission)

*Check out this playlist of our other finishing videos:*

★SOME OF MY FAVORITE CHEAP TOOLS★

★SOME OF MY FAVORITE HAND TOOLS★

★SOME OF MY FAVORITE POWER TOOLS★

★SOME OF MY FAVORITE OTHER TOOLS★

(If you use one of the affiliate links above, we may receive a small commission)

★THIS VIDEO WAS MADE POSSIBLE BY★

*Please help support us by using the link above for a quick look around!*

(If you use one of these affiliate links, we may receive a small commission)

*Check out this playlist of our other finishing videos:*

★SOME OF MY FAVORITE CHEAP TOOLS★

★SOME OF MY FAVORITE HAND TOOLS★

★SOME OF MY FAVORITE POWER TOOLS★

★SOME OF MY FAVORITE OTHER TOOLS★

(If you use one of the affiliate links above, we may receive a small commission)

Watch this before using polyurethane wood finish!

TIPS and techniques on how to apply polyurethane EVENLY like a pro

I figured out why your polyurethane is bumpy!

How To Apply Polyurethane Without Bubbles, Puddles, Runs or Brush Marks | Updated

Don't buy wiping polyurethane! (How to make AND use it properly.)

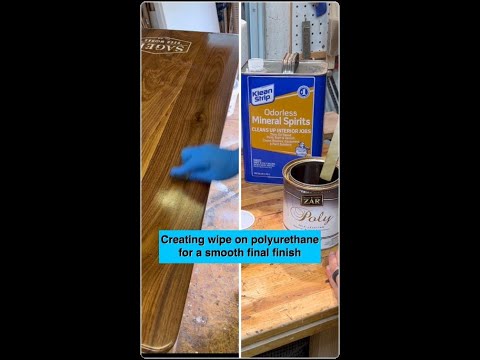

How I get a smooth final coat on my tables #polyurethane #woodfinishing #woodshop

The BEST process for applying oil based polyurethane by hand! #minwax #polyurethane

Differences in 3 types of interior polyurethanes #woodworking #polyurethane

the ULTIMATE Airbrush Primer test – which one is BEST for Warhammer, miniatures?

How To Brush On A Glass Smooth Finish With Oil Based Polyurethane 😲😱🤯👍

How To Apply Water Based Polyurethane. #polyurethane #handyman #clearcoat #howto #diy

What does 40 Coats of Polyurethane Look Like?

How to Polish Polyurethane Perfectly: Quick Guide

HOW TO APPLY POLYURETHANE TO WOOD

How to Apply Polyurethane to Wood | Easy Guide to Finishing Wood with Polyurethane

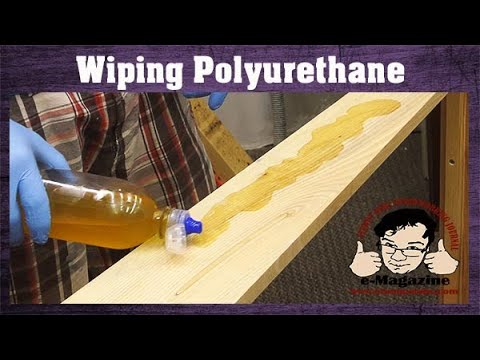

Wiping on polyurethane- 50/50 diluted

How To Apply Polyurethane #hardwood #flooring

How To Apply Polyurethane To Wood Floors

How to apply polyurethane

Improper sanding between coats of finish- HOW TO AVOID IT!

HOW TO APPLY POLYURETHANE TO WOOD | Applying The Polyurethane | Woodworking || #Shorts #Youtubeshort

Best way to apply floor finish? #polyurethane #hardwoodfloors

How I get that glass smooth top with polyurethane Tips and Tricks for Furniture Makeover

#shorts - How to avoid bubbles in your polyurethane.

Комментарии

0:02:01

0:02:01

0:06:47

0:06:47

0:23:53

0:23:53

0:05:11

0:05:11

0:00:34

0:00:34

0:00:39

0:00:39

0:00:44

0:00:44

0:23:38

0:23:38

0:08:05

0:08:05

0:01:01

0:01:01

0:01:50

0:01:50

0:02:02

0:02:02

0:06:16

0:06:16

0:07:54

0:07:54

0:06:01

0:06:01

0:00:15

0:00:15

0:04:56

0:04:56

0:00:19

0:00:19

0:06:44

0:06:44

0:00:24

0:00:24

0:00:16

0:00:16

0:14:53

0:14:53

0:00:14

0:00:14