filmov

tv

BMW Z3 M Coupe: How To Fix The Flawed Chassis Design | Wheeler Dealers

Показать описание

Ant shows how to fix the chassis issues that are the result of a flawed original design by BMW, where the combination of a powerful engine and weak platform undermined the structural integrity of the car.

Why the BMW Z3 M Coupe is a cult HERO | PistonHeads

BMW Z3 M Coupe: How To Fix The Flawed Chassis Design | Wheeler Dealers

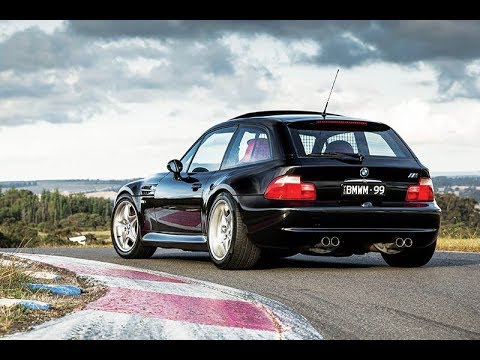

BMW Z3M Coupe | The Freak Show

How the Legendary BMW M Coupe Was Designed in Secret

BMW Z3 M Coupe Review - Worth The Weird?

Audi TTRS vs BMW Z3M Coupe

I bought 9 BMW M Coupes looking for the perfect one

BMW Z3M Coupe Drift

BMW Z3M Coupe Review | Unique Cars Magazine

BMW Z3 M Coupe (E36/8) - Retro Classics 2023 - Stuttgart

Old flames die hard - Imran & Bilal buy an S54 Z3M Coupe

BMW Z3 M Coupe | Rain Drive

2000 BMW M Coupe Review: Ugly Duckling or Future Classic [Kennan]

What It's Like to Own a BMW Z3 M Coupe: Ask The Owner

Super Rare BMW Z3 M Coupe Schnitzer - Sapphire Black. Paint correction & Wheels-off Deep Detail

NEW CAR? BMW Z3 M COUPE (a must see car)

Modified BMW Z3M Coupe S54 - (Texas) One Take

BMW Z3M Coupe - One Take

1999 BMW Z3 M Coupe : #Neversell

BMW Z3M Coupe 'Clown Shoe' DRIVEN | Supercar Driver

BMW Z3M Coupe Acceleration 0-220 km/h GREAT! Beschleunigung

NEW project BMW Z3 M Coupe

The BMW Clownshoe has no equal | The Next Big Thing with Magnus Walker | Ep. 203

Driving one of the Rarest BMW M's | Z3 M Coupe Black Forest Run | RAW SOUND

Комментарии

0:11:48

0:11:48

0:07:22

0:07:22

0:16:01

0:16:01

0:11:08

0:11:08

0:14:36

0:14:36

0:00:19

0:00:19

0:10:18

0:10:18

0:00:23

0:00:23

0:02:15

0:02:15

0:00:51

0:00:51

0:23:24

0:23:24

0:02:48

0:02:48

0:17:29

0:17:29

0:03:03

0:03:03

0:18:07

0:18:07

0:11:22

0:11:22

0:10:10

0:10:10

0:09:23

0:09:23

0:07:43

0:07:43

0:07:06

0:07:06

0:01:05

0:01:05

0:11:57

0:11:57

0:08:57

0:08:57

0:04:55

0:04:55